Working Conditions Of Non-clogging Submersible Sewage Pump

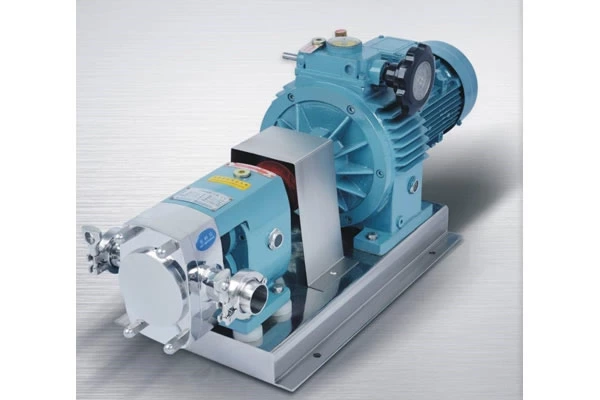

Sanitary Rotary Lobe Pump consists of signal line, motor, impeller, pump body, sealing ring, mechanical seal, oil-water probe, etc. The signal line cooperates with the full protection pump control cabinet to implement all-round protection for the pump, including water leakage, phase failure, short circuit, overheating, motor overload and other items; the oil-water probe is installed in the oil chamber. When the mechanical seal is damaged, water enters the oil chamber, and the probe can send a signal to protect the pump by the control system; the pump body and impeller are matched to make the water pump highly efficient; the sealing ring is installed at the mouth ring of the pump body. When the mouth ring of the impeller is worn due to operation, the sealing ring can be replaced to ensure that the pump runs at the best efficiency.

The non-clogging submersible sewage pump adopts a unique impeller structure and a new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of this pump adopts a single-channel or double-channel form. It is similar to a curved pipe with the same cross-section size and has very good flowability. With a reasonable volute chamber, the pump has high efficiency and the impeller has been tested for dynamic and static balance, so that the pump has no vibration and low noise during operation.

Product features of non-clogging submersible sewage pump:

1. The large-channel anti-clogging hydraulic component design greatly improves the ability to pass dirt, and can effectively pass fibrous materials 5 times the pump diameter and solid particles with a diameter of about 50% of the pump diameter.

2. Advanced design, high efficiency, and significant energy-saving effect.

3. The double-channel series mechanical seal is made of hard and corrosion-resistant tungsten carbide, which is durable and wear-resistant, and can make the pump run safely and continuously for more than 8,000 hours.

4. Compact structure, small size, easy to move, simple installation, no need to build a pump room, reducing engineering costs.

5. An oil-water probe is installed in the oil chamber to provide absolute protection for the pump.

6. It can be equipped with a fully automatic safety protection control cabinet to monitor the water leakage, leakage, overload and overtemperature of the pump to ensure the reliable and safe operation of the pump.

7. The float switch can automatically control the pump to stop and start according to the required water level changes, without the need for special personnel to watch.

8. The motor can adopt a water jacket type external circulation cooling system to ensure the safe operation of the electric pump in a waterless (dry) state.

Working conditions of non-clogging submersible sewage pump:

1. The medium temperature does not exceed 60℃, the weight is 1.0~1.3kg/dm3, and the pH value is used in the range of 5~9.

2. For pumps without self-circulating cooling system, the motor part shall not exceed 1/3 of the liquid surface.

3. During operation, the water pump current shall not exceed the rated current of the motor. In general, the water pump must be used within the use head range to ensure that the motor is not overloaded. If it needs to be used within the full head range, it should be specified separately when ordering.

The non-clogging submersible sewage pump is suitable for the discharge of seriously polluted wastewater from factories and commerce, sewage discharge stations in residential areas, drainage systems of urban sewage treatment plants, drainage stations of civil air defense systems, water supply equipment of water plants, sewage discharge from hospitals and hotels, municipal engineering construction sites, exploration, mining ancillary equipment, rural biogas pools, farmland irrigation and other industries. It can convey sewage and dirt with particles, and can also be used for clean water and corrosive media.