What Is The Reason For Increased Noise And Vibration In Centrifugal Pumps

01 Cavitation

Cavitation is the main cause of noise, vibration and reduced efficiency during the operation of centrifugal pumps. Cavitation not only affects the flow state of the fluid, but also affects its dynamic response. In the long run, cavitation may also cause damage to the surface of the flow-through part of the centrifugal pump, seal failure and bearing wear.

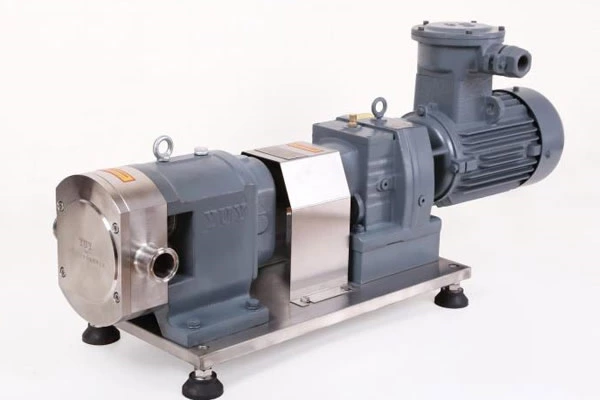

02 The pump shaft is not concentric with the motor

The centrifugal pump used belongs to the centrifugal pump series with couplings. During the installation process or after maintenance, the motor and the pump are connected and installed with a coupling, which causes the motor or pump head to shift, or the balance between the motor and the pump is not adjusted after maintenance. Noise and vibration will occur.

This phenomenon must be corrected to solve it. You can also choose a centrifugal pump without a coupling, such as a single-stage horizontal centrifugal pump.

03 The outlet flow is too large

Many users lack understanding of the performance of centrifugal pumps when choosing centrifugal pump models. When choosing the centrifugal pump head, they think that a high-lift centrifugal pump can be used as long as it is within this head range.

This kind of thinking often leads to the centrifugal pump vibrating and making noise during use. Because the centrifugal pump has a high head but the actual head is low, the pump outlet flow rate will be too large. The large flow rate will cause the suction pipe resistance to be too large, resulting in vibration. In severe cases, it will also cause the motor to overcurrent and burn the motor.

If the centrifugal pump in use is caused by this reason, it is recommended to close the outlet valve or reduce the impeller of the centrifugal pump.

04 Loose foundation or fasteners

Centrifugal pumps that have been used for a long time may have loose foundation bolts or centrifugal pump motor bolts and pump body bolts. Therefore, it is necessary to observe frequently during use. If the bolts are loose, they need to be tightened.

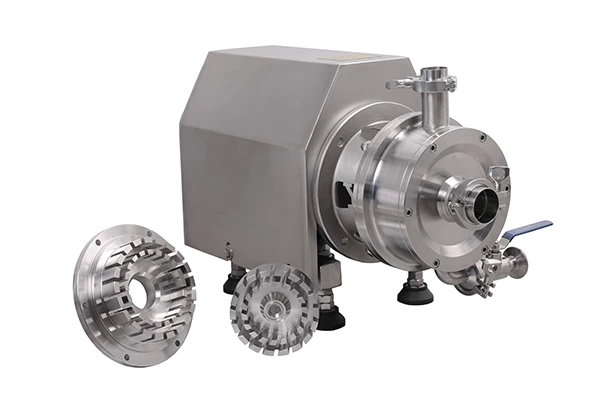

05 Sanitary Centrifugal Pump Bearing damage

Each centrifugal pump bearing has a service life. Wear will occur during high-speed rotation. If there is friction and grinding in the rotating part, there will be relatively loud noise. If there is a lack of oil in the bearing box, it will also cause bearing damage and noise or vibration.

If a centrifugal pump is used for pipeline booster transportation, it is recommended to use a centrifugal pump that is easy to install: The water transported by the pipeline centrifugal pump contains some fine particles such as sand. It is recommended to use a single-stage centrifugal pump.