What Is The Difference Between An Ordinary Centrifugal Pump And A Self-priming Centrifugal Pump

1. The main difference in function:

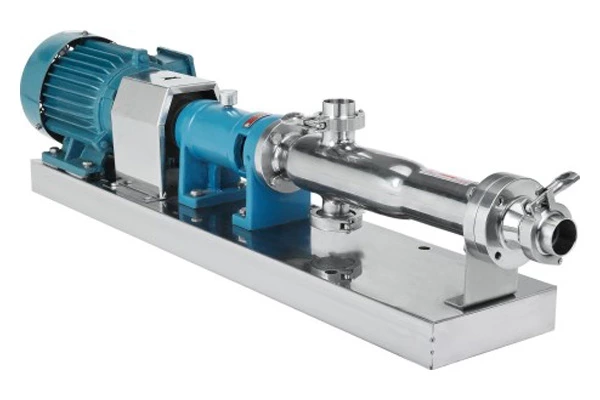

1. Sanitary Centrifugal Pump

Ordinary centrifugal pumps should start filling the lower surface before the impeller is sucked, which is very convenient. With the memory of pumping water, the inlet needs to be filled at the end of the suction valve, and the hydraulic valve pump work has caused great losses.

2. Self-priming centrifugal pumps

Self-priming centrifugal pumps are a type of centrifugal pumps, but compared with centrifugal pumps, its biggest difference is that it has "self-priming" performance.

2. Differences in working principles:

1. Self-priming centrifugal pumps

1) Before starting, a certain amount of starting circulating water should be injected into the pump body when the self-priming centrifugal pump is started for the first time; and the centrifugal pump needs to fill the water inlet pipe and the pump body with water at the same time each time it is started, or use an auxiliary device to pump air from the water inlet pipe.

2) In terms of device, the self-priming centrifugal pump is only equipped with a filter screen at the lower end of the water inlet pipe without a bottom valve; and the centrifugal pump must be equipped with a bottom valve at the lower end of the water inlet pipe or an air extraction device at the outlet.

3) During operation, for pumps with the same performance parameters, the efficiency of self-priming centrifugal pumps is generally lower than that of centrifugal pumps, and the cavitation performance is poorer.

2. Ordinary centrifugal pumps

1) For ordinary centrifugal pumps, if the adsorption surface is lower than the impeller, it needs to be filled with water before it can be started. However, if water needs to be added every time it is started, it is very inconvenient.

2) In order to exhaust the air in the water suction pipeline and form a certain vacuum degree during operation, ordinary centrifugal pumps need to take exhaust measures.

3) For ordinary centrifugal pumps, the pump casing and the water inlet pipe must be filled with water before starting. In order to prevent water leakage, a one-way bottom valve is installed at the bottom of the water inlet pipe, which opens when the water flows upward and closes when it flows downward; generally, centrifugal pumps with a larger water inlet diameter of more than 300mm do not have a bottom valve, but use a special air extraction device to extract air and draw water. This will undoubtedly bring trouble to the start-up of the water pump and cause useless work consumption.