What Are The Advantages Of Stainless Steel Vertical Pipeline Centrifugal Pumps

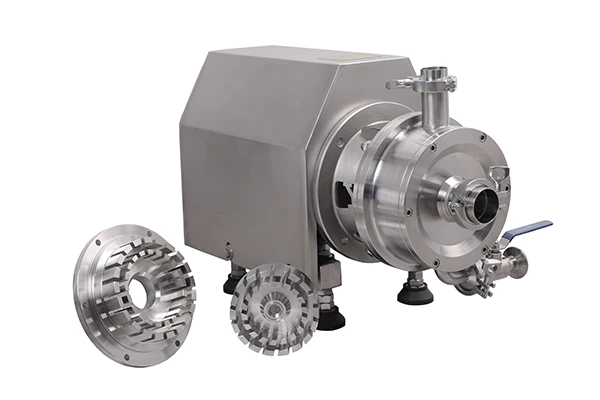

Many friends are familiar with Sanitary Volute Pump. It is mainly divided into two structures: in medium and small pumps with a pump diameter less than or equal to 0.1m, the shaft is coaxial with the motor rotor, and the whole machine consists of a pump body, a cover frame, an impeller, a sealing ring, a mechanical seal and a bleed valve, etc. The mechanical seal is a single-end unbalanced type; in larger pumps with a pump diameter greater than 0.1m, it consists of a pump body, a cover frame, an impeller, a sealing ring, a mechanical seal, a connecting shaft, a bearing, a bearing cover and a bleed valve. The motor shaft is directly sleeved into the connecting shaft hole and drives the connecting shaft through a key. Regardless of the size of the pump, the upper open structure is adopted, that is, as long as the nut on the cover frame is unscrewed, all the parts except the pump body can be taken out; the advantage of the stainless steel vertical pipeline centrifugal pump is that the rotor part can be taken out for maintenance without disassembling the pump body and the pipeline.

Measures to reduce the energy loss of stainless steel vertical pipeline centrifugal pumps:

1. During maintenance and assembly, special attention should be paid to various matching clearances. Too large clearances will cause leakage, and too small clearances will cause friction. Therefore, when assembling each component, it is necessary to strictly follow the process technology requirements and standards.

2. Increase the speed of the pump and reduce the impeller diameter. Because the larger the diameter of the impeller, the greater the friction loss of the disc. According to expert experiments, the friction loss of the disc is proportional to the cube of the speed and the fifth power of the outer diameter of the impeller. Therefore, under the premise of unchanged head, the speed of the pump can be increased, the diameter of the impeller can be reduced accordingly, and the friction loss of the disc can be reduced to the fifth power.

3. Appropriately control the width of both sides of the pump chamber, and at the same time control the width between the impeller outlet side and the pump chamber to the extrusion chamber, so as to provide a smooth channel for the flowing liquid and reduce hydraulic loss.

4. Mechanical seal is used for the shaft seal.

5. Improve the surface roughness of the cover plates, pump body, impeller flow channel and guide vane flow channel on both sides of the impeller, that is, make the flow surface smoother.

6. Change the shape of the sealing ring: Making the sealing ring into a labyrinth or zigzag shape can reduce leakage and volume loss. In response to the requirements of the manufacturing process of the sealing ring, the style should be advanced, the material should be good, and the wear resistance should be high.

Application scope of stainless steel vertical pipeline centrifugal pump:

* HVAC hot and cold water circulation

* Industrial city water supply

* High-rise building booster water supply

* Equipment matching / boiler water supply

* Agricultural irrigation water and other fields

The stainless steel vertical pipeline centrifugal pump adopts the performance parameters of the IS type centrifugal pump and is cleverly combined and designed on the basis of the general vertical pump. At the same time, according to the use temperature, medium, etc., suitable hot water, high temperature, corrosive chemical pumps and oil pumps are dispatched on the basis of the ISG type. The stainless steel vertical pipeline centrifugal pump has the advantages of high efficiency and energy saving, low noise, and reliable performance. It has the characteristics of internal high temperature and corrosion resistance. The new blade impeller is added to the pump body, which has the function of crushing slag and debris. It is a new generation of sewage treatment and chemical environmental protection.