Today Let's Talk About The Corrosion Of Pump Materials

According to ISO8044 and VDI3822, corrosion is the reaction of a metallic material with its surrounding environment. In most cases, this reaction is an electrochemical reaction that only occurs in an electrical conductor solution (electrolyte). This is also called a redox reaction because two reactions occur at the same time, one is anodic oxidation (metal dissolution) and the other is cathodic reduction.

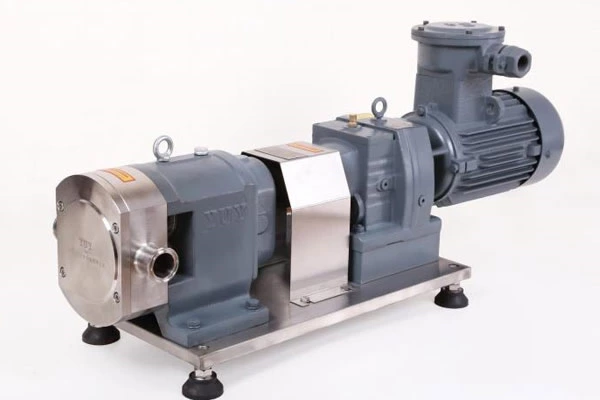

According to ISO8044 and VDI3822, corrosion is the reaction of a Sanitary Rotary Lobe Pump metallic material with its surrounding environment. In most cases, this reaction is an electrochemical reaction that only occurs in an electrical conductor solution (electrolyte). This is also called a redox reaction because two reactions occur at the same time, one is anodic oxidation (metal dissolution) and the other is cathodic reduction.

The result of corrosion is significant changes in the material, leading to impairment of the functionality of the system or component. Corrosion damage can be limited or avoided by anti-corrosion measures.

Different types of corrosion produce different forms of damage. The most common and dominant type of corrosion is wet corrosion.

➤ No mechanical stress

uniform corrosion

Uniform corrosion is corrosion that occurs at the same rate across all or most of the metal surface.

localized corrosion

On the contrary, localized corrosion refers to corrosion that occurs in various parts of the metal surface. The root cause is the local different corrosion loads (temperature, concentration, flow rate, etc.) caused by the formation of corrosion products with different solubilities.

Pitting corrosion

Pitting is an electrochemically limited, localized corrosion of a material that results in the formation of point-like cavities. The root cause is the presence of corrosive factors, mainly chloride. Pitting corrosion is particularly serious on stainless steel and aluminum alloys.

crevice corrosion

Crevice corrosion occurs in narrow gaps between similar metals or between metals and non-metals. Corrosion factors occur because of the increase in chloride or the decrease in oxygen that forms the oxide layer.

Contact corrosion

Contact corrosion (galvanic corrosion) occurs because the corrosion electrode potentials between metals are different, forming corrosion factors. During this period, the metal with lower electrode potential (anode) dissolves faster, and the metal with higher electrode potential becomes the cathode reaction surface. The corrosion rate is determined by the difference in corrosion electrode potential and the ratio of the two reaction surfaces. When the corrosion electrode potentials are very different, it is extremely disadvantageous if the anode area is small and the cathode area is large.

selective corrosion

Selective corrosion is a type of corrosion that preferentially corrodes certain grain boundary components or alloy components. The forms of selective corrosion include graphitization corrosion, intergranular corrosion, dezincification and dealumination, etc.

Graphitized corrosion

Graphitizing corrosion is a selective corrosion in gray cast iron that causes the metal components to dissolve due to insufficient protective layer. In the end, only the original shape of the graphite frame, filled with corrosion products, remains.

intergranular corrosion

Intergranular corrosion refers to preferential corrosion that occurs at grain boundaries. In stainless steel, intergranular corrosion occurs due to the diffusion of carbon to the grain boundaries, resulting in "chromium deficiency". This type of corrosion results in rapid decay of the grains.

Dezincification or dealumination

Dezincification or dealumination is caused by selective corrosion of non-ferrous metals such as zinc or aluminum.

static corrosion

Static corrosion is corrosion that occurs in stagnant liquids and only occurs during periods when the equipment is stopped.

microbial corrosion

Microbial corrosion is corrosion influenced by microorganisms, such as sulfate-reducing bacteria.

➤ With mechanical stress

erosion-corrosion

Erosion-corrosion is the interaction between mechanical surface erosion and corrosion. In this process, erosion occurs because the protective layer is damaged, and the consequence of erosion is corrosion.

cavitation

Cavitation erosion refers to the interaction between cavitation and corrosion. In this process, the protective layer is damaged by local cavitation, which leads to and accelerates corrosion.

friction corrosion

Frictional corrosion refers to corrosion in which the surface layer or passivation layer is damaged due to mechanical friction and is affected by the corrosive medium.

stress corrosion

Stress corrosion refers to the phenomenon of cracks occurring in metal due to the influence of specific corrosive media when it is subjected to various tensile loads. During this process, the material has no obvious corrosion products and brittle fracture.

corrosion fatigue

Corrosion fatigue refers to the phenomenon of low deformation and mostly cross-grain fracture of metals caused by the interaction between mechanical alternating loads and corrosion.