Tips For Controlling The Flow Of Water Pumps

1. Adjustment of outlet valve opening

In this method, the pump is connected in series with the outlet pipeline regulating valve. Its actual effect is like using a new pump system. The maximum output pressure head of the pump has not changed, but the flow curve has been attenuated.

2. Bypass valve adjustment

In this method, the valve and the pump are connected in parallel. Its actual effect is like using a new pump system. The maximum output pressure head of the pump has changed, and the flow curve characteristics have also changed, and the flow curve is closer to a linear shape.

3. Adjust the impeller diameter

This method does not use any external components, and the flow characteristic curve changes with the diameter.

4. Speed control

The change in impeller speed directly changes the flow curve of the pump. The characteristics of the curve do not change. When the speed decreases, the curve becomes flat, and the pressure head and maximum flow rate are reduced.

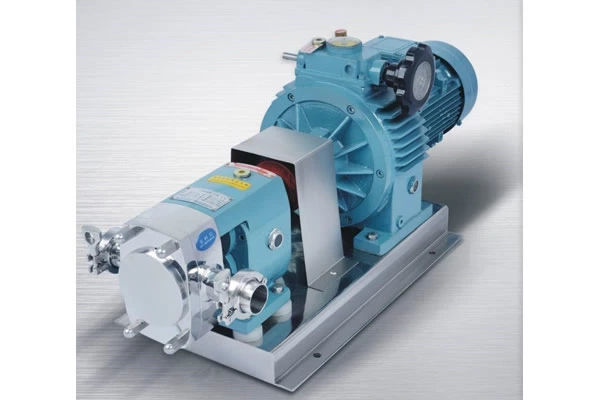

1) Overall efficiency of the Sanitary Rotary Lobe Pump system

Both the outlet valve adjustment and the bypass adjustment methods increase the pipeline pressure loss, and the efficiency of the pump system is greatly reduced. The adjustment of the impeller diameter has little effect on the efficiency of the entire pump system, and the speed control method basically does not affect the system efficiency, as long as the speed is not less than 50% of the normal speed.

2) Energy consumption level

Assuming that the output flow of the pump is adjusted from 60m3/h to 50m3/h through the above four methods, the power consumption when the output is 60m3/h is 100% (the pressure head is 70m at this time), then what is the impact of several flow control methods on the power consumption of the pump?

(1) Adjustment of outlet valve opening, energy consumption is 94%, and power consumption is greater when the flow rate is lower.

(2) Bypass adjustment, the bypass valve reduces the pressure head of the pump to 55M, which can only be achieved by increasing the flow rate of the pump, resulting in an increase in energy consumption of 10%.

(3) Adjustment of impeller diameter, after reducing the impeller diameter, the output flow and pressure of the pump are reduced, and the energy consumption is reduced to 67%.

(4) Speed control, the speed is reduced, the flow rate and pressure head of the pump are reduced, and the energy consumption is reduced to 65%.