The Sanitary Volute Pump Is A High-quality Drainage Equipment Suitable For Environmental Protection.

Sanitary Volute Pump, if the suction liquid level is below the impeller, water should be pre-filled when starting, which is very inconvenient. In order to store water in the pump, a bottom valve needs to be installed at the inlet of the suction pipe. When the sanitary volute pump is working, the bottom valve causes a large hydraulic loss. The so-called sanitary volute pump does not need to be filled with water before starting (it still needs to be filled with water when it is started for the first time after installation). After a short period of operation, the pump itself can suck up the water and put it into normal operation. The sanitary volute pump integrates self-priming and non-blocking sewage discharge. It adopts axial reflux external mixing, and through the unique design of the pump body and impeller flow channel, it can be like a general self-priming clean water pump. It does not need to install a bottom valve and fill water, and can also absorb and discharge liquids containing large solid particles and long fiber impurities.

Self-priming means starting the pump without filling the suction pipe with liquid (but there must be enough liquid in the pump body). The pump itself can automatically remove the gas in the suction pipe and then enter normal operation. The pump must be filled with enough liquid when it is first started. When it is started later, the liquid retained in the pump body will ensure that the pump can be started again. The self-priming time of a self-priming pump refers to the shortest time from pump start to pressure stabilization when the pump is pumping clean liquid at room temperature and the installation height is the allowable suction vacuum ( ) minus 0.5, that is, the time required for the pump to exhaust all the air in the suction pipe. For centrifugal self-priming pumps, the length of the suction pipe between the suction surface and the pump inlet should be less than the pump installation height plus 20D (suction pipe hole diameter); for vortex self-priming pumps, the length of the suction pipe between the suction surface and the pump inlet should be less than the pump installation height plus 2.

Due to the special structure of the sanitary volute pump body, after the water pump stops, there is a certain amount of water in the pump body. After the pump is started again, due to the rotation of the impeller, the air and water in the suction pipe are fully mixed and discharged to the air-water separation chamber. The gas in the upper part of the air-water separation chamber overflows, and the water in the lower part returns to the impeller and remixes with the remaining air in the suction pipe until all the gas in the pump and the suction pipe is discharged, completing self-priming and pumping normally. It combines the water ring wheel and the water pump impeller in a housing, and uses the water ring wheel to discharge the gas to achieve self-priming. When the pump works normally, the valve can be used to cut off the passage between the water ring wheel and the water pump impeller, and the liquid in the water ring wheel can be released. The jet self-priming pump is composed of a centrifugal pump and a jet pump (or ejector). It relies on the ejection device to create a vacuum at the nozzle to achieve suction.

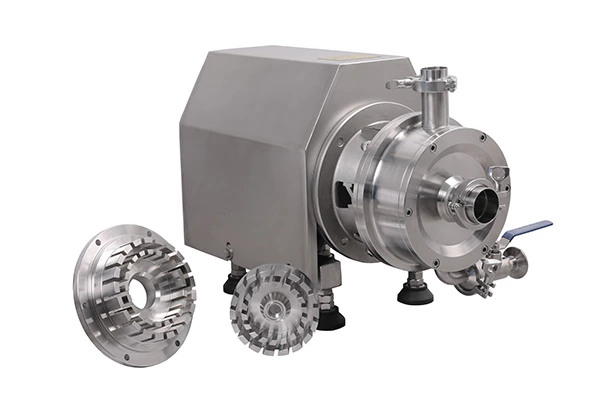

The sanitary volute pump can transport sewage containing larger particles and longer fibers. The impeller is installed in a separate working chamber behind the volute flow channel of the pump body. The sewage and dirt are discharged unimpeded in the volute flow channel of the pump body, shortening the self-priming time and improving the sewage discharge capacity. The simple structure and unique design of the sanitary volute pump not only have low noise and long parts life, but also have the advantages of stable operation and less vibration after the impeller is balanced. At the same time, the parts of the sanitary volute pump are easy to process, and the processing time and materials are reduced, which greatly reduces the cost of the pump, improves the efficiency of the pump, and achieves energy-saving effects. A pump tongue is provided between the air-water separation chamber and the impeller below the liquid outlet of the sanitary volute pump. The air-water separation chamber is connected to the reflux chamber, which is connected to the pump cavity through the reflux hole. The pump tongue is recessed into the air-water separation chamber and forms a certain distance between the impeller and the pump. The sanitary volute pump overcomes the defects of the general sanitary volute pump, such as the complex production process, low reliability and high failure rate. It has the advantages of simple structure, wide application range and high reliability. It is a high-quality drainage equipment suitable for environmental protection, urban construction and other industries.