The Most Critical Issue Of Emulsification Pump

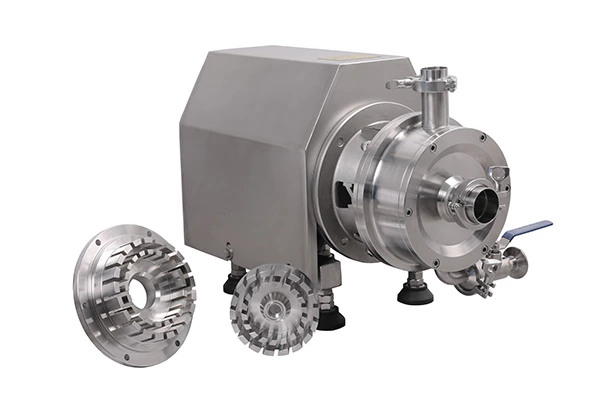

Emulsification Pump is a single-stage vertical structure, a new type of sewage pump successfully developed on the basis of emulsification pump. Made of cast iron or stainless steel, equipped with EP spraying technology exclusively introduced by our company, it has strong corrosion resistance. This series of pumps adopts a unique impeller structure and a new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of the emulsification pump adopts a single-channel or double-channel form. It is similar to a curved pipe with the same cross-section size, with very good flowability, and equipped with a reasonable volute chamber, so that the pump has high efficiency, and the impeller has been tested for dynamic and static balance, so that the pump has no vibration during operation.

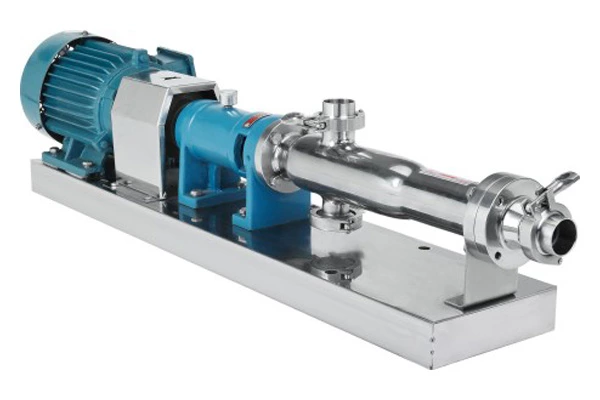

The emulsification pump has a compact structure, small size, easy to move and simple installation. It can be equipped with a liquid level automatic control cabinet to automatically control the start and stop of the pump according to the required liquid level changes. No special person is required to watch it, and it is extremely convenient to use. It is a vertical structure. When working, the pump body is immersed in the liquid, so it is easy to start, there is no problem of exhaust and evacuation, and it has the characteristics of no leakage, etc. The underwater depth can reach 7 meters. The shaft connection structure is advanced and reliable. The pump and the motor are connected by a coupling. The pump shaft size is precise, which ensures the smooth operation of the pump and leaves enough safety factor.

For the emulsification pump, the most critical issue is the availability issue, because the emulsification pump is used underwater; the medium to be transported is a mixed liquid containing some solid materials; the pump and the motor are very close; the pump is arranged vertically, and the weight of the rotating parts is in the same direction as the water pressure borne by the impeller. These problems make the requirements of the emulsification pump in terms of sealing, motor load capacity, bearing arrangement and selection higher than those of ordinary sewage pumps. In order to increase the life of the emulsification pump, most manufacturers at home and abroad are now thinking about the pump protection system, that is, when the pump leaks, overloads, overheats and other faults occur, it can automatically alarm and automatically shut down for repair. However, we believe that it is necessary to set up a protection system in the emulsification pump, which can effectively protect the safe operation of the electric pump.

Because the emulsification pump adopts a unique double-suction double-flow channel structure, in actual operation, the water enters from both ends of the water pump impeller at the same time and flows out from the middle. The water inlet of the water pump is divided into two parts, upper and lower, and both draw water from the bottom. The water absorption direction is low. Because water is absorbed from both ends, one end of the isolation oil chamber between the pump and the motor is at the water inlet position, and it is always in a negative pressure state during operation. It is not easy to leak compared to the single-suction structure. Because the pump absorbs water from both ends at the same time, the motor has no axial tension, and the double-channel structure reduces the radial force, thereby extending its service life and achieving the functions of durability, stability and practicality. A high-precision anti-interference water leakage detection sensor is set in the sealing oil chamber of the emulsification pump, and a thermistor is embedded in the stator winding to automatically protect the water pump motor. According to user needs, it can be equipped with a fully automatic control cabinet to automatically protect the pump from water leakage, leakage, overload and overtemperature, etc., which improves the safety and reliability of the product. The float opening can automatically control the start and stop of the pump according to the required liquid level changes, without the need for special personnel to supervise, and is extremely convenient to use. The emulsification pump can be equipped with a double-rail automatic coupling installation system according to user needs, which brings greater convenience to installation and maintenance, and people do not need to enter the sewage pit for this purpose.