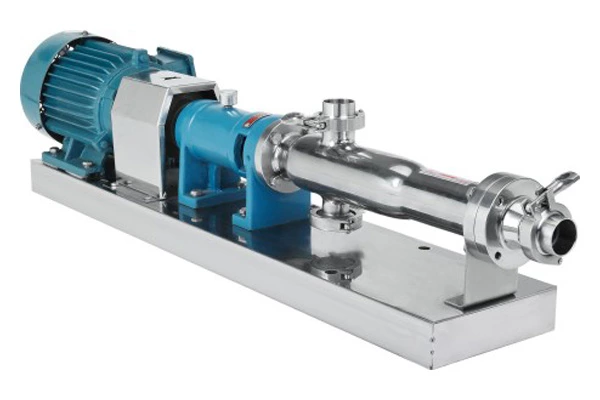

Ten Requirements For Installing Sanitary Rotary Lobe Pump Manufacturers' Sanitary Rotary Lobe Pumps

The working principle of the sanitary rotary cam pump of the manufacturer Sanitary Rotary Lobe Pump is: fill the pump casing with water before starting the water pump (or there is water in the pump casing itself). After starting, the impeller rotates at high speed to make the water in the impeller groove flow to the volute. At this time, a vacuum is formed at the inlet, so that the water inlet check valve opens, and the air in the suction pipe enters the pump and reaches the outer edge through the impeller groove. The self-priming sewage pump is a self-priming centrifugal pump. It has the advantages of compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long life, and strong self-priming ability. The pipeline does not need to install a bottom valve. Before working, it is only necessary to ensure that there is a quantitative lead liquid stored in the pump body. Different materials of sanitary rotary cam pumps can be used for different liquids.

Ten requirements for installing the sanitary rotary cam pump of the manufacturer of sanitary rotary cam pumps:

1. The coupling of the sanitary rotary cam pump must be firmly fixed with a nut, and the nut must be locked to prevent the nut from loosening, otherwise it is easy to cause the impeller to move and cause mechanical failure.

2. When the sanitary rotary cam pump is directly connected to the motor, attention should be paid to the coaxiality between the pump shaft and the motor output; the accuracy of the pump installation has a great impact on the running stability and service life of the pump, so it must be carefully installed and corrected.

3. In order to keep a certain amount of storage liquid in the sanitary rotary cam pump body to achieve better self-priming ability and prevent dry friction of the mechanical seal, the pump inlet must be higher than the center line of the pump shaft.

4. The installation of the suction pipeline should pay attention to:

A. The installation height of the suction port cannot exceed 5 meters. When conditions permit, the installation height of the suction port should be as low as possible below the lowest storage level of the pool, and the length of the suction pipe should be shortened as much as possible, and fewer elbows should be installed, which is conducive to shortening the self-priming time and improving the self-priming function.

B. Valves, flanges, etc. in the suction pipeline should be strictly prevented from leaking or leaking liquid, that is, no leakage is allowed in the suction pipeline.

C. The sanitary rotary cam pump body of the sanitary rotary cam pump manufacturer should be prevented from sucking in solids and other debris. For this reason, a filter should be installed on the suction pipeline. The effective water flow area of the filter should be 2-3 times the cross-section of the suction pipe, and the filter should be checked regularly.

D. The suction and discharge pipes should have their own brackets, and the pump body itself is not allowed to bear the load of the pipe.

5. When installing the sanitary rotary cam pump, strictly check whether there are stones, iron sand and other debris in the pump housing and pipes.

6. Correct the installation clearance and coaxiality of the sanitary rotary cam pump coupling and the motor coupling. The allowable deviation of the misalignment is 0.1mm. The height difference between the pump shaft and the motor shaft can be adjusted by padding copper or iron on the base.

7. When installing the sanitary rotary cam pump of the sanitary rotary cam pump manufacturer, the electrostatic grounding resistance of the pump and the pipe should meet the specified requirements.

8. After the unit is actually running for 3-4 hours, make a final inspection. If there is no adverse phenomenon, the main installation is complete, and the shaft should be checked during the trial operation.

9. The cooling water joint of the sanitary rotary cam pump bearing body with a cooling chamber device is used for a hose or plastic pipe with an inner hole of 12, and its thread size is M12x1.75.

10. If a one-way valve is installed on the outlet pipe of the sanitary rotary cam pump and the pump cannot discharge gas smoothly during the self-priming process, an exhaust water pipe and valve should be added at the outlet of the pump.

The development and advent of the sanitary rotary cam pump by the sanitary rotary cam pump manufacturer can be said to be an innovation of the original conveying system. First of all, this pump cancels the long axis of the submersible pump, and all the troublesome bearings are abandoned. Secondly, the main components of the sanitary rotary cam pump are above the ground, and there is no mechanical structure under the conveying medium. Therefore, daily maintenance and overhaul become very quick and convenient. Then there is a great improvement in the head. The suction range of the sanitary rotary cam pump can reach up to about 7 meters (special structure will be higher), which is a qualitative leap compared to the submersible pump.