Technology: Water Hammer Is A Harmful Thing

When an open valve is suddenly closed, the water flow will generate a pressure on the valve and the pipe wall. Because the pipe wall is smooth, the subsequent water flow quickly reaches the maximum under the action of inertia and produces a destructive effect. This is the "water hammer effect" in fluid mechanics, that is, positive water hammer. This factor must be considered in the construction of water supply pipelines.

On the contrary, a closed valve will also produce water hammer after it is suddenly opened, called negative water hammer, which also has a certain destructive power, but not as great as the former. When the electric water pump unit suddenly loses power or starts, it will also cause pressure shock and water hammer effect. This pressure shock wave propagates along the pipeline, which can easily cause local overpressure in the pipeline, causing pipeline rupture and damage to equipment, etc. Therefore, water hammer effect protection has become one of the key process technologies for water supply projects.

Conditions for water hammer

1. Sudden opening or closing of valves;

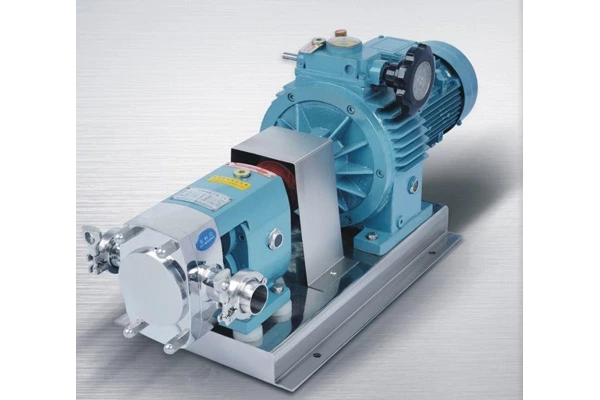

2. Sudden shutdown or opening of Sanitary Centrifugal Pump units;

3. Water is delivered to a high place through a single pipe (the height difference of the water supply terrain exceeds 20 meters);

4. The total head (or working pressure) of the water pump is large;

5. The water flow velocity in the water pipeline is too high;

6. The water pipeline is too long and the terrain changes greatly.

Hazards of water hammer effect

The pressure increase caused by water hammer can reach several times or even dozens of times the normal working pressure of the pipeline. This large pressure fluctuation has the following main hazards to the pipeline system:

1. It causes strong vibration of the pipeline and disconnection of the pipeline joint;

2. It damages the valve. Severe overpressure causes the pipeline to burst and the pressure of the water supply network to decrease;

3. On the contrary, too low pressure will cause the collapse of the pipe and damage the valve and fixings;

4. It causes the water pump to reverse and damage the equipment or pipeline in the pump room. In severe cases, it will cause the pump room to be flooded, causing major accidents such as personal injury and death, affecting production and life.

Protection measures to eliminate or reduce water hammer

There are many protection measures for water hammer, but different measures should be taken according to the possible causes of water hammer.

1. Reducing the flow rate of the water pipeline can reduce the water hammer pressure to a certain extent, but it will increase the diameter of the water pipeline and increase the project investment. When arranging the water pipeline, it should be considered to avoid humps or sudden changes in slope as much as possible. The size of the pump stop water hammer is mainly related to the geometric head of the pump room. The higher the geometric head, the greater the pump stop water hammer value. Therefore, a reasonable pump head should be selected according to the actual local conditions. After the pump is stopped due to an accident, the water pump should be started after the pipe behind the check valve is filled with water. When starting the pump, do not fully open the outlet valve of the pump, otherwise it will cause a large water shock. Many major water hammer accidents in pumping stations occur in this situation.

2. Set up a water hammer elimination device

(1) Use constant pressure control technology:

Since the pressure of the water supply network changes with the change of working conditions, low pressure or overpressure often occurs during the operation of the system, which is easy to cause water hammer, resulting in damage to pipelines and equipment. An automatic control system is used to detect the pressure of the network, feedback control the start, stop and speed adjustment of the water pump, control the flow rate, and then maintain a certain level of pressure. The water supply pressure of the pump can be set by controlling the microcomputer to maintain constant pressure water supply, avoid excessive pressure fluctuations, and reduce the probability of water hammer.

(2) Install water hammer eliminator

This device is mainly used to prevent water hammer when the pump stops. It is usually installed near the outlet pipe of the water pump and uses the pressure of the pipe itself as power to realize low-pressure automatic operation. That is, when the pressure in the pipe is lower than the set protection value, the drain outlet will automatically open to release water and release pressure to balance the pressure of the local pipe and prevent water hammer from impacting the equipment and pipes. Eliminators can generally be divided into mechanical and hydraulic types. Mechanical eliminators are manually restored after operation, while hydraulic eliminators can be automatically reset.

(3) Install slow-closing check valves on the outlet pipes of large-diameter water pumps

It can effectively eliminate water hammer when the pump stops, but because a certain amount of water will flow back when the valve is operated, the suction well must have an overflow pipe. Slow-closing check valves are of two types: heavy hammer type and energy storage type. This valve can adjust the valve closing time within a certain range as needed. Generally, the valve is closed 70% to 80% within 3 to 7 seconds after the power outage, and the remaining 20% to 30% of the closing time is adjusted according to the conditions of the water pump and the pipeline, generally in the range of 10 to 30 seconds. It is worth noting that when there is a hump in the pipeline and a bridge water hammer occurs, the slow-closing check valve is very effective.

(4) Set up a one-way pressure regulating tower

It is built near the pump station or at an appropriate location in the pipeline. The height of the one-way pressure regulating tower is lower than the pipeline pressure at that location. When the pressure in the pipeline is lower than the water level in the tower, the pressure regulating tower replenishes water to the pipeline to prevent the water column from breaking and avoid bridge water hammer. However, its pressure-reducing effect on water hammers other than pump stop water hammer, such as valve closing water hammer, is limited. In addition, the performance of the one-way valve used in the one-way pressure regulating tower must be absolutely reliable. Once the valve fails, it may cause a large

(5) Set up a bypass pipe (valve) in the pump station

When the pump system is operating normally, the water pressure on the pump pressure side is higher than the water pressure on the suction side, and the check valve is closed. When the pump is suddenly stopped due to a power outage, the pressure at the outlet of the pump station drops sharply, while the pressure on the suction side rises sharply. Under this differential pressure, the transient high-pressure water in the suction main pipe pushes the check valve plate to flow to the transient low-pressure water in the pressure main pipe, and the low water pressure there is increased; on the other hand, the water hammer pressure rise on the suction side of the pump is also reduced. In this way, the water hammer pressure rise and pressure drop on both sides of the pump station are controlled, thereby effectively reducing and preventing water hammer hazards.

(6) Install multi-stage check valves

In a long water pipeline, one or more check valves are added to divide the water pipeline into several sections, and a check valve is installed on each section. When the water in the water pipeline flows back during the water hammer process, the check valves are closed successively to divide the backwash water flow into several sections. Since the hydrostatic head in each section of the water pipeline (or backwash water flow section) is quite small, the water hammer pressure rise is reduced. This protective measure can be effectively used in situations where the geometric water supply height difference is large; but it cannot eliminate the possibility of water column separation. Its biggest disadvantage is that the power consumption of the water pump increases during normal operation and the water supply cost increases.