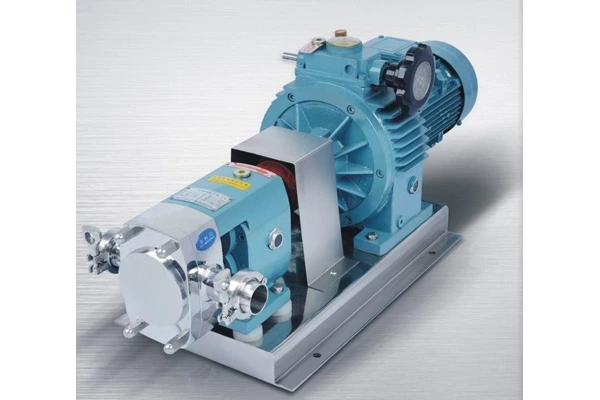

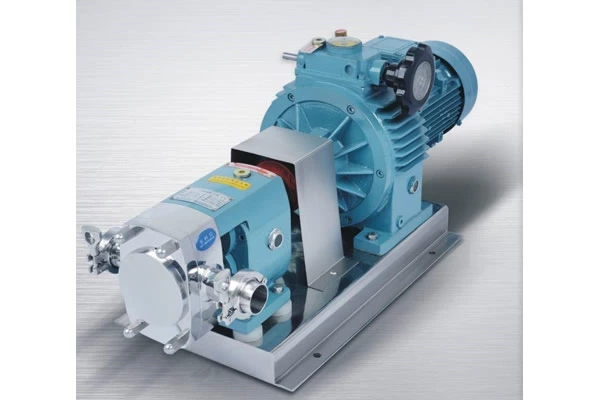

Technical Use Of Sanitary Rotary Lobe Pumps

The rotation of the internal turbine causes the water to rise, and the internal pressure decreases. Due to the atmospheric pressure, the water enters the turbine part again. In fact, it is also a water pump, which is usually installed directly on the water pipe and is called Sanitary Rotary Lobe Pump.

Civilian small sanitary rotary cam pumps are often used to increase water pressure on water pipes with insufficient water pressure, and can also be used in other water circulation systems.

The sanitary rotary cam pump is composed of a motor housing 1, a motor stator 2, a motor rotor 3, a sealing sleeve 4, a water pump housing 5, a water pump impeller 6, an end cover 7, a motor shaft 8, a filter 9, an end cover groove 10, a sealing rubber ring 11 and a graphite bearing 12. It is characterized in that the sealing sleeve 4 shields the motor stator 2 and the motor rotor 3 and seals them with a sealing rubber ring 11. There is a filter 9 in the end cover 7, and there is an end cover groove 10 on the end cover 7. The bearing adopts a graphite sliding bearing 12, the water pump impeller 6 adopts modified polyphenylene ether PPO plastic, and the motor housing 1 adopts die-cast aluminum alloy or cast iron material. The power supply voltage is commonly 380v/3 phase, 220v/single phase AC. The general power ranges from a few watts to several hundred watts.

Characteristics and functions of sanitary rotary cam pumps

The sanitary rotary cam pump is a novel pump developed for pipeline boosting and delivery to solve the problem of low pipeline pressure. It has great advantages over the currently used horizontal centrifugal pumps. The sanitary rotary cam pump has the following characteristics:

1. The sanitary rotary cam pump has a compact structure, integrated machine and pump, and a small size. Its vertical structure has a small installation footprint, stable operation, and no adjustment is required for installation.

2. The pump inlet and outlet are designed with flanges of the same specifications and are located on the same center line. They can be directly installed on the pipeline like a valve, and the center is low, which is convenient for pipeline layout and installation.

3. The pump is coaxial with the motor and has a short axial dimension, making the pump run more smoothly and with low noise.

4. The traditional shaft seal method is cancelled to avoid the leakage of the conveying medium, so it has the remarkable characteristic of being completely leak-free.

The role of the sanitary rotary cam pump

The sanitary rotary cam pump is a novel pump developed for pipeline boosting and delivery to solve the problem of low pipeline pressure. It has great advantages over the currently used horizontal centrifugal pump. The advantages of the sanitary rotary cam pump are mainly reflected in the following points:

1. The sanitary rotary cam pump is suitable for high-rise building boosting water supply, garden sprinkler irrigation, cooling tower water supply, long-distance water supply, air conditioning, refrigeration flushing, bathroom and other cold and warm water circulation pressurization. The use temperature is below 80℃.

2. Sanitary rotary cam pumps are suitable for high-temperature hot water booster circulation in heating, boiler and other industries. The use temperature is below 150℃.

3. Sanitary rotary cam pumps are suitable for conveying corrosive media in the process of food, pharmaceutical, wine making, chemical and other industries, and the use temperature is below 80℃.

4. Sanitary rotary cam pumps are suitable for conveying non-corrosive liquids, methane or coal mine underground fixed equipment Class I and factory IIA. IIB level, temperature groups T1, T2, T3, T4 groups and other industrial places with explosive mixtures. The use temperature is below 80℃.

5. Sanitary rotary cam pumps are suitable for conveying corrosive liquids in industries such as chemical, pharmaceutical, petroleum, food, and national defense, methane or coal mine underground fixed equipment Class I and factory IIA. IIB level, temperature groups T1, T2, T3, T4 groups and other industrial places with explosive mixtures. The use temperature is below 150℃.