Teach You How To Calculate The Flow And Head Of The Water Pump

1. Pump selection criteria

① The selected pump model meets the parameters of the pump device flow, head, pressure, temperature, cavitation flow, suction head, etc.;

② The pump has high mechanical authenticity, low noise and low vibration

③ In terms of cost, the customer should consider the pump equipment operation fee, subsequent maintenance fee and management fee.

2. Determination of pump flow

Flow is one of the important parameters for CIP Return Pump selection, which directly affects the production capacity and delivery capacity of the pump. The design institute generally calculates the normal, minimum and maximum flow rates of the pump. The maximum flow rate is generally used as the basis for pump selection. If there is no maximum flow rate of the pump, 1.1 times the normal flow rate of the pump is generally taken as the maximum flow rate.

When selecting the pump flow rate, the parameters on the pump product sample are generally used to select the pump flow rate. For example, the flow rate can be selected as 1.1 to 1.2 times the rated flow rate of the air source unit (1.1 for a single unit and 1.2 for two units in parallel) or calculated according to the following formula:

Q=1.163L*ΔT

—Q is the cooling capacity of the air source unit

—L is the system cooling water flow rate

—ΔT is the system temperature difference

L(m3/h)= Q(kW)/(4.5-5)℃x1.163X(1.1-1.2)

3. Determination of pump head

Pump head composition: Hmax=△P1+△P2, △P1 is the pipeline resistance along the way, and △P2 is the local resistance of the pipeline.

(1) System pressure loss along the way

Pressure along the way refers to the continuous and consistent pressure loss in the pump pipeline. Find the most unfavorable loop in the pump pipeline and the farthest and most resistant branch pipe loop in the pipeline network system as the most unfavorable loop in the pipeline network system.

△P1=most unfavorable pipeline length*specific friction resistance

Generally, it is estimated that the loss along the pipeline for every 100 meters of pipeline length is 5mH2O

(2) System local resistance

Local pressure loss refers to the discontinuous pressure loss caused by special components in the pipeline system, which change the direction of water flow or narrow the local water flow channel (such as reduction, tee, valve, joint, filter, etc.). The local resistance is mainly composed of the following.

① Water resistance of air source unit: generally 6-8mH2O; (For specific values, please refer to product samples)

② Water resistance of surface cooler or evaporator of terminal equipment (air handling unit, fan coil, etc.): generally 5-7mH2O; (For specific values, please refer to product samples)

③ Resistance of return water filter, generally 3-5mH2O;

④ Water resistance of valve (check valve): generally 3mH2O per valve;

⑤ Local resistance loss of tee and joints of refrigeration system water pipeline: generally 3-4mH2O;

In summary, according to the calculated total resistance, a safety factor of 10% is taken to obtain the pump head

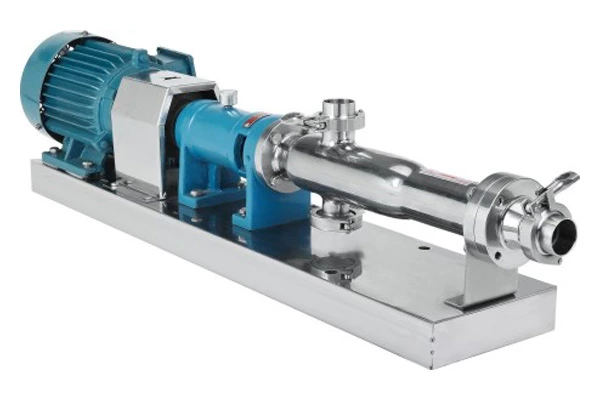

Before selecting the pump, the conveying medium must be determined. If it is clean water, cast iron centrifugal water pump products can be selected. For sewage, pneumatic pumps or sewage pump products can be selected. If the conveying medium is corrosive, stainless steel or fluoroplastic materials need to be selected.

In the sample selection parameter table of water pump products, select the head value that is consistent with or close to the design head; then find the flow value that is consistent with or close to the design flow in the vertical header. The vertical and horizontal lines intersect in a small square, which marks the model of the water pump. Preliminary selection of the pump model. Sometimes there will be two models that meet the design requirements. At this time, it is necessary to make a comparison and conduct an economic benefit analysis and comparison, and then select a suitable model of water pump for the customer. If the design flow and head of the water pump are relatively large, a single pump cannot meet its requirements, then you can consider choosing a multi-stage pump to meet its needs. Try to select a water pump with a flow and head close to the customer's requirements, which is also conducive to the later operation, maintenance and management of the water pump.