Summarize the types, uses and structural characteristics of stainless steel sanitary centrifugal pumps

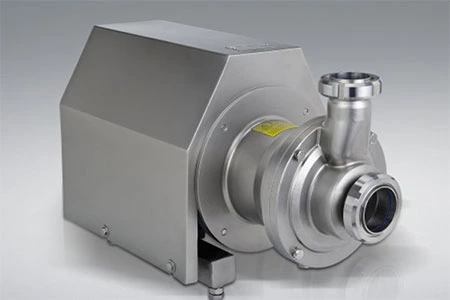

The stainless steel sanitary centrifugal pump is a sanitary pump made of stainless steel , which can be used under different environmental conditions with different operating temperatures and media. Stainless steel sanitary centrifugal pump has the advantages of high efficiency, energy saving, low noise, reliable performance and beautiful appearance. This article mainly introduces the use and structural characteristics of stainless steel sanitary centrifugal pumps. The details are as follows:

Types and uses of stainless steel sanitary pumps:

A, FB1 (FM) food grade negative pressure pumps , for conveying liquids without solid particles, applicable temperature In the range of -20℃~70℃, it is widely used in chemical, petroleum, metallurgy, food, wine, synthetic fiber, medicine and other sectors;

B and FNB horizontal centrifugal pumps are used to transport liquids containing a small amount of small solid particles. The temperature is in the range of -20℃~150℃, widely used in starch, chemical, petroleum, food, wine, synthetic fiber, medicine and other sectors;

C, FRN type horizontal centrifugal pumps are used to transport liquids containing a small amount of small solid particles. The applicable temperature is in the range of -20℃~25℃, widely used in sugar, beverage, starch, pharmacy, metallurgy, synthetic fiber and other sectors;

D, JM type horizontal centrifugal wine pump for conveying various alcohol, beverage, dairy products , Pharmaceuticals, gasoline, solvents, syrups, etc., the temperature is in the range of -35℃~80℃.

Structural features of stainless steel sanitary centrifugal pump:

A. The pump is a horizontal structure, made of all stainless steel, compact and beautiful, easy to operate, small in size, and light in weight;

B. The shaft seal is assembled with a new type of mechanical seal and is sealed with imported titanium alloy. The ring, wear-resistant and high-temperature resistant material, can effectively extend the service life of the sealing device;

C. It is convenient to install and maintain, fixed and mobile. The fixed pump inlet and outlet adopt flange type, and the movable inlet and outlet adopt beam joint type.