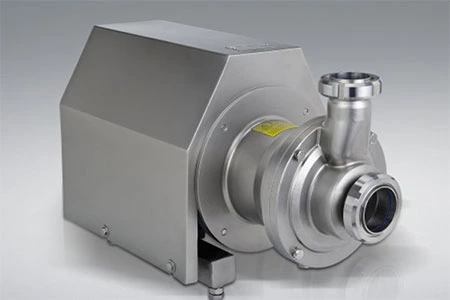

Stainless steel sanitary pump design standards and installation

Stainless steel sanitary pump design standards and installation

Please check, the following points must be met:

1. Whether the power supply calibrated on the motor nameplate is consistent with the on-site power supply;

2. Whether the driving device is intact (whether it is damaged during transportation or storage);

3. Whether the stainless steel centrifugal pump meets the special environmental conditions (whether it is flammable and explosive ring mirror, whether it is acid-corrosive ring mirror).

Installation location: The foundation of the stainless steel negative pressure pump should generally be a flat ground with sufficient strength

The pump set should be installed as far as possible in the lowest position of the equipment, that is, at the position with the highest lift height;

Pipeline installation

The diameter of the pipeline and the inlet and outlet of the pump should be the same, and the inlet pipe diameter should not be too small. (When the diameter of the pipe is smaller than that of the pump, adjust it with an eccentric reducer to shorten the small diameter pipe as much as possible to avoid the formation of air pockets.) The outlet pipe diameter should not be too large. When the outlet pipe diameter is larger than the pump outlet, try to extend it as much as possible To sanitary pump outlet