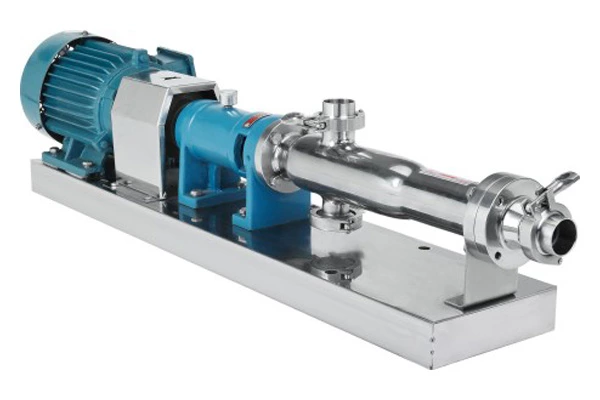

Single Screw Pump Has Two Flushing Modes

Single Screw Pump has the characteristics of significant energy saving, spinning winding, no clogging, automatic installation and automatic control. It has unique effects in discharging solid particles and long fiber garbage. The pump of this product adopts a unique impeller structure and a new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of this pump adopts a single flow channel or a double flow channel. It is similar to a curved pipe with the same cross-section size, has very good flowability, and is equipped with a reasonable volute chamber, so that the pump has high efficiency, and the impeller has been tested for dynamic and static balance, so that the pump is vibration-free and low noise during operation.

During the use of the single screw pump, it is necessary to select the appropriate sealing method according to the actual situation: packing seal or mechanical seal. The long-axis submersible pump pumps the liquid directly from a separate liquid outlet pipe, and there will be no liquid leakage in the axial position. Therefore, under normal circumstances, a shaft seal is not required. However, if the liquid is toxic, volatile, and not allowed to leak into the atmosphere in a closed container, a shaft seal needs to be installed. If the requirements for the shaft seal are not too strict, a packing seal can be used. If the requirements for the seal are more stringent, a mechanical seal should be used.

The installation and maintenance of single screw pumps are difficult, and the tools used are complex. Therefore, the use of submersible pumps should be based on the requirements of the factory to formulate a reasonable use and maintenance cycle. Dismantle and repair and maintain before failure to reduce the abnormal failure rate affecting production, facilitate disassembly and inspection, reduce unnecessary damage to parts, and reduce operating costs.

According to the different pumping media, the flushing method should be reasonably selected. During the operation of the single screw pump, the friction between the sliding bearing and the sleeve will generate a lot of heat, and it must be fully and timely flushed to achieve the effect of cooling and lubrication. The correct selection of flushing method affects the safe operation of the pump. Single screw pumps usually have two flushing methods: self-flushing and external flushing:

1. Self-flushing method: This flushing method can be used when the pumping medium is a clean medium. Lead a pipeline at the pump outlet flange to allow the flushing liquid to flow to each sliding bearing, lubricate the bearing and take away the heat generated by the friction pair, reducing the bearing temperature.

2. External flushing method: When the pumping medium contains small particles, it is necessary to connect a pipeline from the outside to introduce clean flushing liquid to flush and lubricate the bearings, take away the heat generated by the friction pair, and prevent solid particles from entering the friction pair. In sewage treatment systems, external flushing is more common.