Selection Of Sanitary Centrifugal Pump Models

Sanitary Centrifugal Pump is a combination of excellent hydraulic models selected by our scientific and technological personnel and domestic water pump experts, using the performance parameters of IS centrifugal pumps, and cleverly designed on the basis of general vertical pumps. At the same time, according to the use temperature, medium, etc., suitable hot water, high temperature, corrosive chemical pumps and oil pumps are dispatched on the basis of ISG type. Sanitary centrifugal pumps have the advantages of high efficiency and energy saving, low noise, and reliable performance.

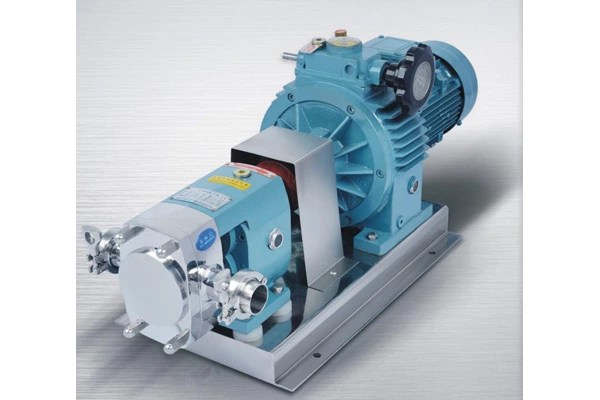

Sanitary centrifugal pump model:

Sanitary centrifugal pumps are widely used. Depending on the model, pipeline centrifugal pumps can be used in energy, chemical, textile, papermaking, irrigation, urban water supply and other fields. The use temperature range is wide and corrosion-resistant, but when selecting the model, you must pay attention to the fact that pipeline centrifugal pumps are not universal, so the model must be selected correctly.

Features of sanitary centrifugal pumps

1. The sanitary centrifugal pump is a vertical structure with the same inlet and outlet diameters and located on the same center line. It can be installed in the pipeline like a valve. It has a compact and beautiful appearance, small footprint, and low construction investment. If a protective cover is added, it can be placed outdoors for use.

2. The impeller is directly installed on the extended shaft of the motor, with short axial dimensions and compact structure. The pump and motor bearings are reasonably configured, which can effectively balance the radial and axial loads generated by the operation of the pump, thereby ensuring the smooth operation of the pump, low vibration and low noise.

3. The shaft seal adopts mechanical seal or mechanical seal combination, imported titanium alloy sealing ring, medium-sized high-temperature resistant mechanical seal and hard alloy material, wear-resistant seal, which can effectively extend the service life of the mechanical seal.

4. The sanitary centrifugal pump is easy to install and repair. There is no need to dismantle the pipeline system. All rotor components can be pulled out by removing the pump union seat nut.

5. The series and parallel operation modes of the pump can be adopted according to the use requirements, that is, the flow rate and head requirements.

6. The vertical and horizontal installation of the pump can be adopted according to the requirements of the pipeline layout.

Sanitary centrifugal pumps are used to transport clean water and other liquids with physical and chemical properties similar to clean water. They are suitable for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire fighting pressurization, long-distance transportation, HVAC refrigeration cycle, bathroom and other hot and cold water circulation pressurization and equipment matching. The operating temperature T is less than 80℃.