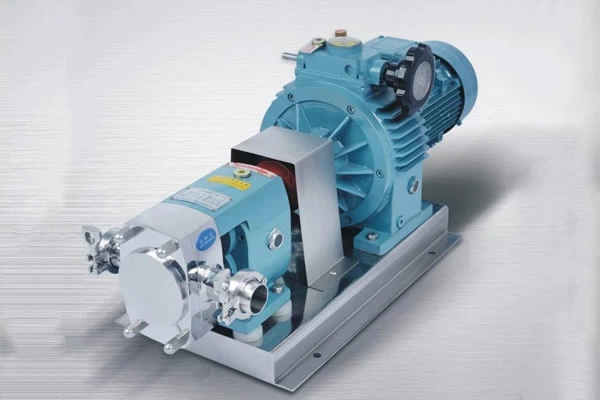

Sanitary Rotor Pump Knowledge Popularization

Sanitary Rotary Lobe Pump is a pump specially designed for sanitary fields such as food, pharmaceuticals, and beverages. It has the following features and applications:

1. Material selection: Sanitary rotor pumps usually use high-quality stainless steel materials, such as 316L stainless steel, to ensure the sanitary requirements of the fluid. This material has good corrosion resistance and high temperature resistance, which can effectively avoid contamination of the fluid.

2. Sanitary design: The sanitary rotor pump has a sanitary design, its internal structure is simple and easy to clean, and avoids dead corners and liquid accumulation problems. At the same time, the interface and sealing components of the pump are also specially designed to ensure the cleanliness and hygiene of the pump.

3. High efficiency: Sanitary rotor pumps usually have excellent self-priming performance and fluid delivery capacity, and can stably and efficiently deliver sanitary liquids. They have higher flow and lower pulsation, which can meet the requirements of sanitary processes.

4. Wide range of applications: Sanitary rotor pumps are suitable for many sanitary applications, such as food processing, pharmaceutical industry, beverage production, cosmetics production, etc. They are often used in processes such as liquid delivery, filling, mixing and circulation.

5. Hygienic certification: Sanitary rotor pumps usually need to pass relevant hygiene certifications, such as FDA (U.S. Food and Drug Administration) certification, EHEDG (European Hygienic Design Engineering Federation) certification, etc. These certifications can ensure that the pump meets hygiene standards and is suitable for applications in the sanitary field.

In general, sanitary rotor pumps are characterized by hygienic design, high efficiency, material selection and wide application. They play a vital role in the sanitary field, helping to ensure the hygiene and quality requirements of the production process.