Sanitary Rotary Vane Pumps Have Three Outlet Directions

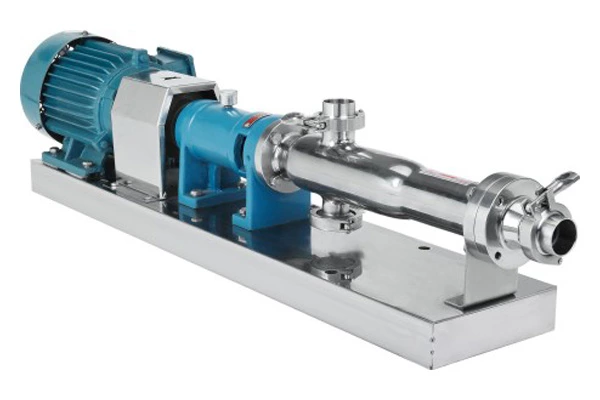

Sanitary Rotary Lobe Pump is designed according to the international standard ISO2858. It is a derivative series of IH standard chemical pumps. Its basic size and performance are the same as those of IH pumps. The sanitary rotary vane pump is a self-priming centrifugal pump. It has the advantages of compact structure, convenient operation, balanced operation, convenient maintenance, high efficiency, long life, and strong self-priming ability. There is no need to install a foot valve in the pipeline. Before working, it is only necessary to keep a quantitative amount of lead liquid in the pump body, thus simplifying the pipeline system and improving working conditions. The sanitary rotary vane pump is an energy-saving and efficient product with stable performance, various sealing forms, and standardized component sizes. This series of pumps cancels the suction management foot valve. As long as there is a small amount of liquid in the pump body, it is no longer necessary to fill the lead liquid when starting, and it is completely vacuumed by itself; after the liquid is sucked up, it can work, and its self-priming height can reach 6-8 meters. Within this range, it can replace the submersible pump. Different from other sanitary rotary vane pumps that can only work at a height of less than 5m, work at a temperature below 120 degrees, and have a single sealing form, the IHZ type has greatly improved the function and scope of use of sanitary rotary vane pumps.

Product features of sanitary rotary vane pumps:

Smooth operation: The absolute concentricity of the sanitary rotary vane pump and the excellent dynamic and static balance of the impeller ensure smooth operation without vibration.

Watertight: Carbide seals of different materials ensure that there is no leakage in the transportation of different media.

Low noise: The water pump supported by two low-noise bearings runs smoothly, except for the faint sound of the motor, there is basically no noise.

Low failure rate: The structure of the sanitary rotary vane pump is simple and reasonable, and the key parts are of international first-class quality; matching, the trouble-free working time of the whole machine is greatly improved.

Convenient maintenance: Replacement of seals and bearings is simple and convenient.

Less space: The outlet can be in three directions: left, right, and upward. The sanitary rotary vane pump is convenient for pipeline layout and installation, saving space.

Sanitary rotary vane pumps are suitable for conveying corrosive liquids, cleaning systems, food processing, medicine and health, sewage treatment, electroplating, bleaching and dyeing, fine chemicals, environmental protection projects or other industrial systems.