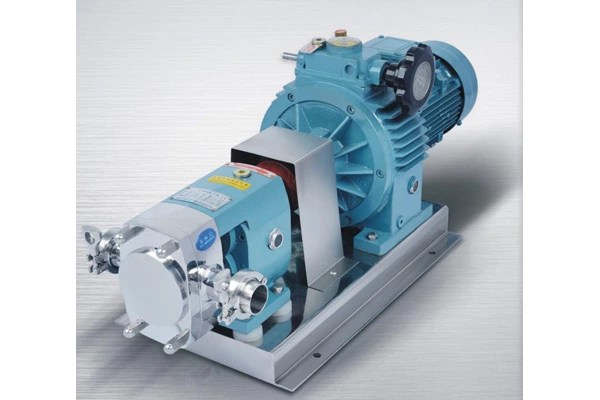

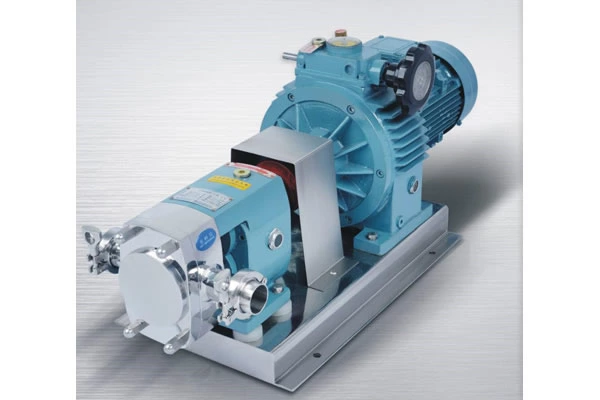

Sanitary Rotary Lobe Pump Product Introduction And Usage Conditions

Sanitary Rotary Lobe Pump is a new type of vertical single-stage centrifugal pump developed for pressurized water supply in high-rise buildings and to solve the problem of low pipeline pressure. It has great advantages over the currently used horizontal centrifugal pumps. The sanitary rotary cam pump adopts advanced mechanical seals, and the motor main shaft is directly installed with the impeller, so it has the characteristics of less leakage, high efficiency, low power consumption, compact structure, small size, light weight, convenient decoration, and can be used in series according to the needs of head and flow. As a replacement product of conventional centrifugal pumps, this pump has replaced a variety of old pumps and has been widely used in various industries, which has become a general trend.

The use conditions of sanitary rotary cam pumps are as follows:

1. The water pressure of the inlet pipe is not more than 3 kg/cm2;

2. The water quality is clear water, and there should be no fibers or solid particles. The hot water should be soft water;

3. Medium temperature: cold water is not lower than 0℃;

4. The ambient temperature does not exceed ±45℃;

5. The power supply voltage is 380V, and some are 220V.

Reasons for the decline in the efficiency of sanitary rotary cam pumps

1. Due to the scouring of water flow, the inner wall of the water pump flow channel and the water surface of the impeller become rough and uneven, the friction coefficient of the water pump flow channel increases, and the water flow rate in the pump is very high, the head loss increases, and the hydraulic efficiency decreases;

2. Due to the addition of drugs or water quality before the pump, the pump casing is seriously scaled or corroded. Severe scale accumulation in the pump casing can increase the thickness of the pump casing by about 2ram, and the inner wall of the water pump forms a scale tumor, which reduces the volume of the pump body, reduces the amount of water pumped, and the flow channel is rough, and the head loss increases. Both the volumetric efficiency and the hydraulic efficiency are reduced;

3. Due to casting defects, cavitation, abrasion, corrosion and chemical erosion caused by the processing technology of the water pump, cavities or cracks are generated in the pump flow channel, and vortices are generated when the water flows, causing energy loss and reducing the hydraulic efficiency;

4. Cavitation on the surface of the impeller. Because the negative pressure is generated when the blades are running on the back of the water, when the pressure Pk

5. Volumetric loss and mechanical loss. Due to the long service life of the pump, mechanical wear and tear will cause leakage and increase resistance, which will reduce the volumetric efficiency and mechanical efficiency.

The above reasons will cause the performance of the water pump to deteriorate. The operating efficiency will be reduced by 2-5%, and in severe cases, the water pump efficiency can be reduced by more than 10%.