Sanitary Pumps Help Food Safety, And The Demand For Customized Production Lines Continues To Grow

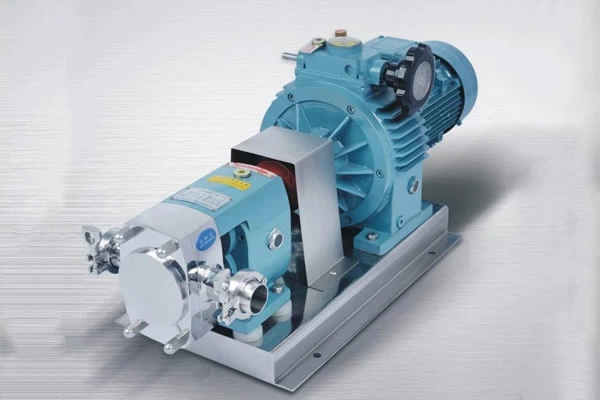

In recent years, with the continuous improvement of people's awareness of food safety, the importance of Sanitary Rotary Lobe Pump in the food processing industry has become increasingly prominent. As a specially designed pump equipment, the sanitary pump has the advantages of no dead angle, easy cleaning, and no leakage, and has become a key process equipment in the food industry. Recent market research data shows that the demand for customized production lines has grown rapidly, bringing new development opportunities to the sanitary pump industry.

Sanitary pumps are mainly used in food, beverage, pharmaceutical and other industries, and play an important role in transportation, mixing, filling, etc. during the processing process. Its special design structure enables it to effectively avoid cross contamination and ensure the hygiene and safety of food. Compared with traditional pumps, sanitary pumps are made of high-quality stainless steel materials, with a smooth surface, no dead angles in the internal structure, easy to clean and disinfect, and greatly reduce the risk of contamination during food processing.

With the continuous increase in customized demand, the sanitary pump industry is facing new development opportunities. Traditional pumps cannot meet the personalized requirements of different food processing companies, while sanitary pumps can be customized according to customer needs, including flow, pressure, material and other requirements. This customized production can better meet the special production needs of food processing companies, improve production efficiency and reduce costs.

In order to better meet market demand, sanitary pump manufacturers are also constantly innovating technology and upgrading products. Some companies have launched more intelligent, energy-saving and environmentally friendly sanitary pump products. By introducing advanced control systems and energy efficiency optimization designs, the performance stability and energy utilization efficiency of the equipment are improved, further improving the competitiveness and market share of the products.

In summary, sanitary pumps, as important equipment in the food processing industry, have been widely used. With the continuous improvement of market requirements for food safety and the growth of customized production demand, the sanitary pump industry will usher in a broader development space. Enterprises should increase investment in technology research and development and innovation, and continuously improve product quality and service levels to meet market demand and enhance competitiveness.