Sanitary Beverage Pump Instructions

3. Hydraulic curve and efficiency curve with water as medium

4. Structural principle

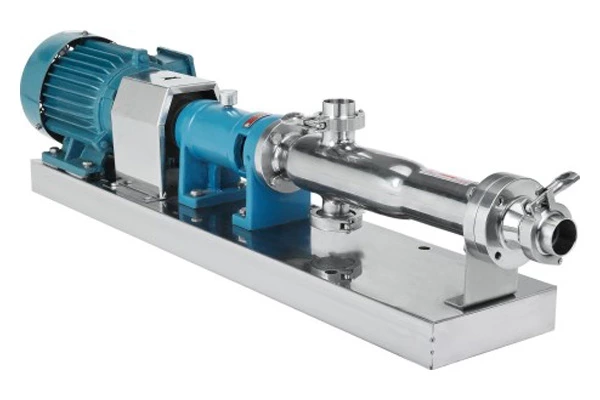

The centrifugal beverage pump consists of: (1) motor, (2) pump housing (I), (3) pump housing (II), (4) impeller, (5) clamping ring, (6) support foot, etc.

The motor and pump housing (I) are connected to the support foot with bolts. The support foot can be moved arbitrarily without the need for a clamping ring to tighten it and rubber seal. The pump housing (I) and the pump housing (II) match each other without being fixed, so that the outlet head of the pump can be installed at any angle.

The impeller is made of 2Cr13. In order to prevent bacteria from gathering, it is easy to install, disassemble and rinse.

Operating machine parts: A 4Cr13 stainless steel connecting shaft is installed on the fully enclosed motor shaft. A stainless steel spring, rubber gasket, and electric carbon graphite products form a mechanical seal structure to prevent liquid leakage.

5. Use and Maintenance

Emulsification Pump can be installed at any angle according to different needs. Before use, check whether the rotation direction of the rotating shaft is correct, whether the nuts of the pipe joints at the pump inlet and outlet are tightened, and whether the sealing ring between the pump casing is well padded. Steam disinfection should be applied before use to ensure food hygiene. In order to avoid the need to fill the pump when the pump is installed at a position higher than the suction liquid level, the pump installation position must be lower than the suction liquid level. After use, the pump chamber should be immediately assembled and cleaned to prevent the material from sticking and corroding. When cleaning, hot water can be passed through first, and then assembled and disassembled. Use a brush to pump all parts that contact the material. After cleaning, connect them in order accordingly. There is a small hole on the pump casing flange. If there is liquid leaking out of the small hole, it means that the shaft seal is leaking. Stop using it immediately, check the fit between the shaft and the hole and the mechanical seal device. If it is severely worn, it should be replaced and ground before use.