Requirements For Medium Viscosity Of Sanitary Rotary Lobe Pumps

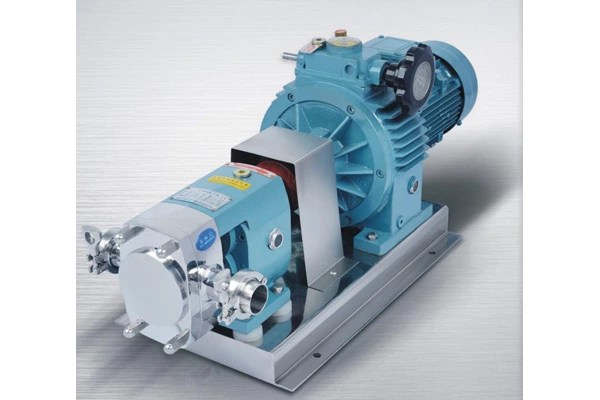

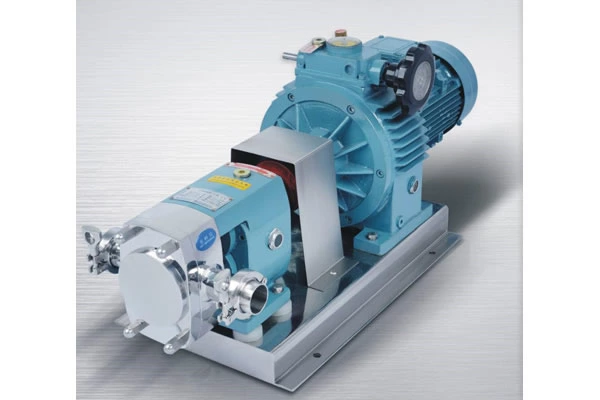

Sanitary Rotary Lobe Pump is a nationally jointly designed energy-saving pump. The performance and technical requirements of the pump are designed according to the performance and dimensions specified in the international standard ISO2858. Its advantages are: reasonable layout of the whole series of hydraulic performance, wide range of user selection, "rear open" structure, convenient maintenance, efficiency and suction reach the international advanced level.

Sanitary rotary cam pumps are widely used in various fields of the chemical industry. At present, the sanitary rotary cam pumps produced by domestic manufacturers mainly include: IH stainless steel sanitary rotary cam pump, IHF fluoroplastic sanitary rotary cam pump, FSB fluoroplastic sanitary rotary cam pump, CQB sanitary rotary cam pump, CQ sanitary rotary cam pump, FZB sanitary rotary cam pump, etc. These sanitary rotary cam pumps are widely used in chemical, metallurgical, pharmaceutical, chemical foil and other industries, and have important uses.

The sanitary rotary cam pump includes a pump body and a shaft. The water inlet pipe and the suction cover are connected by bolts and fixed to the left side of the pump body by stoppers and screws. The sleeve, sleeve gasket and impeller are fixed to the shaft by impeller nuts. The mechanical seal is installed on the sleeve. The shaft is installed in the bearing frame through the bearing. The pump cover is provided on the left side of the bearing frame. The structure of the sanitary rotary cam pump is simple and easy to maintain.

The viscosity of the medium has a great influence on the performance of the pump. When the viscosity increases, the head curve of the pump decreases, and the head and flow rate of the optimal working condition decrease accordingly, while the power increases accordingly, thereby reducing the efficiency. The parameters on the general samples are the performance when conveying clear water. When conveying viscous media, they should be converted. For the conveying of slurries, pastes and viscous liquids with higher viscosity, it is recommended to use a screw pump. The G single screw pump is suitable for medium viscosities of up to 1000000cst.