Reasons Why The Emulsification Pump Cannot Turn

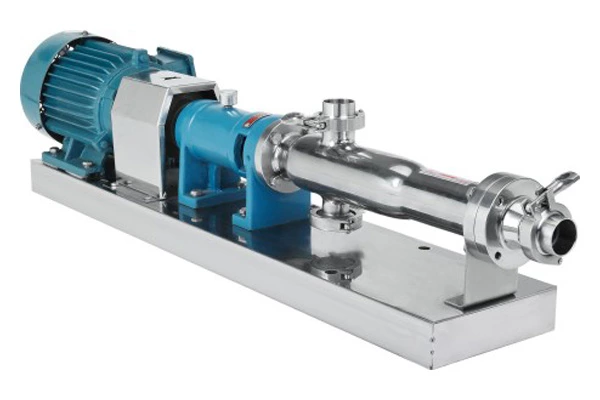

Emulsification Pump is the most commonly used pump in the sewage pump series, because it does not require the construction of a separate pump room. Usually, it takes a lot of time and cost to build a pump room. The emulsified pump series only needs to connect the outlet pipe and hoist the pump into the pool and turn on the power supply to put it into use. The emulsified pump with large flow and heavy weight can be installed in a coupled manner, which is also very convenient for maintenance. It only needs to fix the coupling device at the bottom of the pool, and the pump with the coupling slides along the guide rail of the coupler to the bottom of the pool and automatically matches the outlet flange of the coupling device before it can be put into use.

The emulsified pump is made of the latest model. There will be no overcurrent when running at full head. In addition, it can also add automatic stirring function and belt cutting function on the basis of ordinary emulsified pumps. All products can be made of stainless steel shell according to needs, with more stable performance and improved efficiency, and the whole body appearance is more beautiful and generous.

However, the emulsification pump in use will inevitably encounter the phenomenon of the submersible pump not turning, and when encountering this phenomenon, the reason why the submersible pump cannot turn is unknown. The following introduces the reasons why the emulsification pump cannot turn:

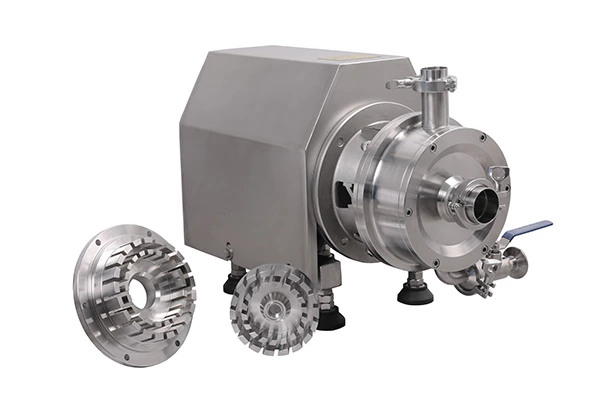

1. If the emulsification pump used is an automatic stirring emulsification pump with a stirring function, it is very likely that the fibers or other debris contained in the conveyed liquid are entangled on the impeller or blocked in the pump body, causing the emulsification pump to not turn.

2. The conveyed liquid is corrosive. Ordinary cast iron sewage pumps are easily corroded. The impeller nut is loosened after corrosion, causing the impeller to contact the submersible pump body, so the submersible pump cannot turn. It is recommended to use stainless steel submersible pump products made of stainless steel.

3. The bearing of the submersible pump is damaged, causing the submersible pump to get stuck and the pump control cabinet to trip as soon as it is started. At this time, a new bearing should be replaced.

4. After replacing the new bearing, the submersible pump still cannot rotate. At this time, the reason why the submersible pump cannot rotate may also be the problem of the motor rotor of the submersible pump. Since the diameter of the motor rotor is slightly thicker, the submersible pump motor is difficult to rotate. In this case, the only way to solve the problem is to replace the new motor rotor or remove the old motor rotor and then turn it on a lathe to remove about 30 microns.