Pump Performance Characteristics

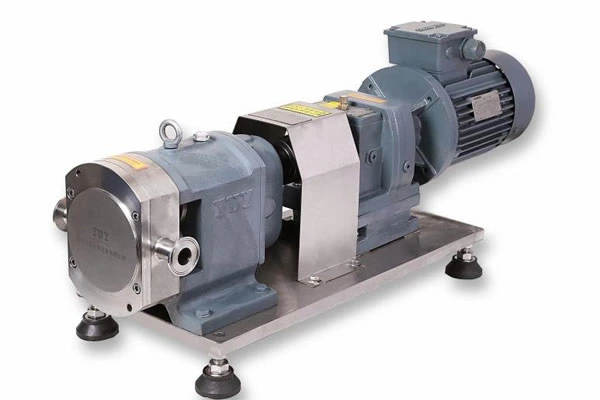

Sanitary Rotary Lobe Pump the suction port and discharge port are both below the pump axis. When inspecting, just open the pump cover and all parts can be removed for maintenance. The S-type pump is mainly composed of a pump body, a pump cover, a shaft, an impeller, a sealing ring, a sleeve, a bearing component, etc.

It is mainly used to transport clean water without solid particles or other liquids with physical and chemical properties similar to water. It is suitable for industrial and urban water supply and drainage, and farmland irrigation and drainage.

Product features:

Sealing system: The mechanical seals and packing seals available for selection use internal circulation for cooling and lubrication;

Large flow and high efficiency: Double-suction impeller has the characteristics of large flow and high efficiency;

Replaceable sleeve: The sleeve is a consumable part that protects the shaft and increases the service life of the pump;

Sealing ring: The sealing ring is a consumable part that improves the efficiency of the pump and extends the service life of the pump.

Working conditions:

Flow range: 30~6500m3/h

Lift range H: 8~140m

Medium temperature: -20℃~+80℃

Ambient temperature: ≤+40℃

The main components of AS submersible sewage pump are impeller, pump body, base, and submersible motor. The pump shaft and motor shaft are the same shaft. Since the pump is located at the bottom of the entire sewage pump, it can maximize the suction of residual sewage on the ground.

AS submersible sewage pump has a tearing structure that can tear and cut fibers and other materials, and then discharge them smoothly. Therefore, this type of pump is particularly suitable for conveying sewage containing long fibers.

Product features:

Durable and waterproof cable: heavy-duty rubber-sheathed soft cable resistant to dirt, resin infusion, pressed and fixed, never loose, long-term and reliable.

Double seal, double protection: two mechanical seals are configured in series to truly achieve double protection and ensure motor safety.

Multi-channel detection, multi-channel protection: equipped with control cabinet, oil and water probe, float switch, all can detect in real time, and can realize alarm, shutdown, retain fault signal and other functions, making the submersible motor safe and reliable.

Easy maintenance: the coupling device of double guide rails can be used, so that the pump does not need underwater operation when it is lifted and lowered, which is convenient for maintenance and saves time and labor; the dedicated electric control cabinet realizes the functions of automatic alarm, shutdown, and retaining fault signals, which can greatly improve the maintenance efficiency.

Full-condition operation: the special hydraulic design is adopted to ensure that the pump can operate without overload under full-condition operation.

Working conditions:

Flow range: 6~180m3/h

Lift range: 3~17m

Speed n: 1450~2900r/min

Ambient temperature T: ≤+40℃

Medium temperature: -15℃~+60℃

Medium density: ≤1.3X103kg/m3

Medium PH value range: 5~9

System maximum working pressure: ≤0.6Mpa

GDL is a vertical single-suction multi-stage pipeline centrifugal pump with suction and discharge ports located on the same straight line. The product complies with JB/T2727-93 "Vertical multi-stage barrel centrifugal pump type and basic parameters" standard.

IHG vertical chemical pump

IHG vertical pipeline chemical pump is widely used in petroleum, chemical, textile printing and dyeing, pharmaceutical, food, metallurgy, power station and other industries to transport corrosive media and media with special requirements. The product complies with GB5656-1994 "Centrifugal Pump Technical Conditions (II) Class" standard.