Pump Layout Strategy

Pump layout

1. Open-air layout

Sanitary Centrifugal Pump are generally arranged under or on the side of the pipe gallery, or near the pumped equipment. The main advantages are good ventilation and convenient operation and repair. If the pump is arranged under the pipe gallery, the center line of the pump outlet should be aligned and 0.6m away from the center line of the pipe gallery column.

2. Semi-open-air layout

Pumps arranged in the semi-open-air are suitable for rainy areas. Generally, the pump is arranged under the pipe gallery, and a ceiling is set on the upper part of the pipeline. Or the pump is arranged on the lower ground of the frame, with the frame platform as the ceiling. According to the layout requirements of the pump, the pump is arranged in single row, double row or multiple rows.

3. Indoor layout

Indoor pumps are suitable for cold or windy and sandy areas, as well as occasions with special process requirements.

Pump layout requirements

1. For pumps arranged in the open air or semi-open air, the axis of the pump and the prime mover is generally perpendicular to the axis of the pipe gallery.

2. For indoor pumps, when the temperature of the conveying liquid is higher than the auto-ignition point or the conveying liquid is liquid hydrocarbon, they should be arranged in their own rooms separately from other pumps and separated by fire walls.

When the pump is arranged indoors, the traffic requirements of motorized maintenance vehicles are generally not considered. The clear distance between the pump end or pump side and the wall should not be less than 1.2~1.5m, and the clear distance between two rows of pumps should not be less than 2m.

3. The positioning dimensions on the equipment layout drawing are based on the axis of the pump unit and the center line of the outlet flange. The elevation of the equipment is uniformly expressed by the elevation of the lower surface of the pump base (i.e. the top surface of the pump foundation). Note: When calculating NPSHa in the professional system of each engineering company, the top surface of the pump foundation is used as the standard, not the elevation of the inlet center line of the pump. The NPSHr of the pump factory is based on the inlet center line of the pump, and the difference between the two is the center height of the pump.

4. The pump group should be arranged neatly, and it is recommended to align with the outlet center line of the pump.

5. The electrical profession and the process or layout profession should coordinate in time. When possible, the motor part of the pump should be kept out of the explosion-proof area as much as possible to save investment.

6. The pump should be as close to the liquid supply equipment as possible to prevent the NPSHa from being too small.

7. The power side and pump side of the steam reciprocating pump should have a position for withdrawing the piston and the pull rod.

8. When the vertical pump is arranged under the pipe gallery or under the frame, the space required for the installation and maintenance of the pump body should be reserved above it.

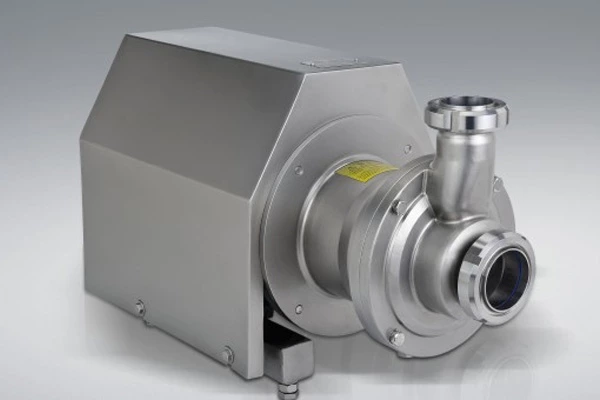

9. The space required for maintenance and inspection of various centrifugal pumps is shown in Figures 1, 2 and 3. When arranging the pipeline, at least one side of the pump should be reserved for maintenance.

Pump installation spacing

The net distance between the two pumps should not be less than 700mm, and the width of the operation channel at the front end of the pump should not be less than 1000mm. For multi-stage pumps, the width of the maintenance channel at the front end of the pump should not be less than 1800mm. The width of the front maintenance channel of the general pump should not be less than 1250mm to facilitate the passage of small forklifts.