Pipeline Pump Installation And Fault Analysis

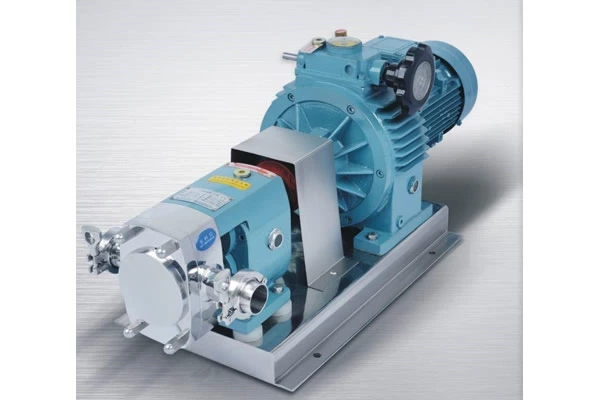

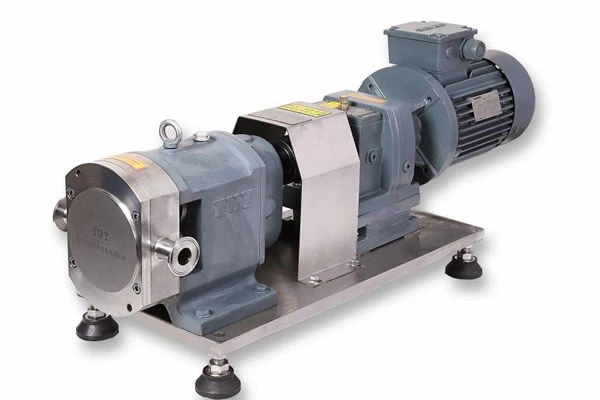

Sanitary Rotary Lobe Pump Installation Instructions:

1. Before installation, check whether the unit fasteners are loose and whether the pump body flow channel is blocked by foreign objects to avoid damage to the impeller and pump body during operation of the water pump.

2. The weight of the pipeline should not be added to the water pump during installation to avoid deformation of the pump.

3. The anchor bolts must be tightened during installation to avoid the impact of vibration on the pump performance during startup.

4. For easy maintenance and safe use, install a regulating valve on the inlet and outlet pipes of the pump and a pressure gauge near the pump outlet to ensure operation within the rated head and flow range, ensure normal operation of the pump, and increase the service life of the water pump.

5. After installation, move the pump shaft, and there should be no friction or jamming of the impeller. Otherwise, the pump should be disassembled to check the cause.

6. The pump is divided into two types: hard connection installation and soft connection installation (see connection method).