Pay Attention To The Conveying Medium Of Self-priming Sewage Pump

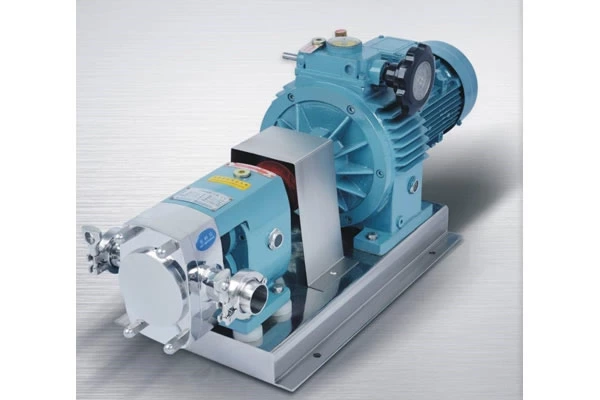

The most critical issue for Sanitary Rotary Lobe Pump is reliability, because the medium to be transported is a mixed liquid containing solid materials. This problem makes the requirements of the sewage pump in terms of sealing, motor load capacity, bearing arrangement and selection higher than that of ordinary pumps. Therefore, when selecting, it is necessary to understand the sealing reliability and load capacity of the sewage pump. In order to improve the life of the sewage pump, most manufacturers at home and abroad are now thinking about the pump protection system, that is, when the pump leaks, overloads, overheats and other faults occur, it can automatically alarm and automatically shut down for repair. It is necessary to set up a protection system in the sewage pump, which can effectively protect the safe operation of the electric pump. But this is not the key to the problem. The protection system is just a remedy after the pump fails, which is a relatively passive method. The key to the problem should be to start from the root and thoroughly solve the problems of the pump in terms of sealing, overload, etc. This is a more active method.

The head of the self-priming sewage pump is determined according to the lifting height and the pipeline loss is calculated. If the medium to be transported is a mixed liquid containing some solid media (such as mud and sand), this problem makes the requirements of the sewage pump in terms of motor load capacity, bearing arrangement, pump body sealing, etc. higher than that of general water pumps. Generally speaking, you should choose a self-priming sewage pump or a self-priming sewage pump. When selecting and ordering, you must understand clearly whether the sealing and load capacity of the sewage pump you choose are suitable.

The self-priming sewage pump adopts a unique single-blade or double-blade impeller structure, which greatly improves the dirt passing capacity. It can effectively pass fibrous materials 5 times the pump diameter and solid particles with a diameter of about 50% of the pump diameter. The mechanical seal adopts a new hard and corrosion-resistant tungsten carbide material. At the same time, the seal is improved to a double-end face seal, so that it can run in the oil chamber for a long time, which can make the pump run safely and continuously for more than 8,000 hours. The self-priming sewage pump is equipped with a high-precision anti-interference water leakage detection sensor in the sealed oil chamber, and the stator winding is pre-buried with a thermal sensitive element, which absolutely protects the water pump motor.

The float switch can automatically control the start and stop of the pump according to the required liquid changes. It does not require special personnel to supervise and is extremely convenient to use. The sewage pumps used in buildings include self-priming sewage pumps, submerged drainage pumps, vertical sewage pumps and horizontal sewage pumps. However, vertical sewage pumps and horizontal sewage pumps require the installation of seismic isolation foundations and occupy a certain amount of site space, so they are rarely used in buildings.

When the flow rate exceeds the design operating point flow rate and reaches a certain value, the input power of the pump may exceed the rated power of the motor, causing the motor to overload and burn. When the motor is overloaded, either the protection system will act to stop the pump from rotating; or the protection system will fail to cause the motor to burn. The situation where the pump head is lower than the design operating point head is often encountered in practice. One situation is that when selecting the pump, the pump head is selected too high, and the pump is used with a lower head in actual use; another situation is that the operating point of the pump is not easy to determine during use. In other words, the flow of the pump needs to be adjusted frequently; another situation is that the pump needs to be used in a different location frequently. These three situations may cause the pump to be overloaded and affect the reliability of the pump. It can be said that for pumps without full head characteristics (including sewage pumps), their scope of use will be greatly limited.

The so-called full head characteristics of self-priming sewage pumps (also known as no overload characteristics) refer to the speed at which the power curve rises very slowly with the increase of flow rate. It is more ideal that when the flow rate increases to a certain value, the power will not rise again, but will decrease. In other words, the power curve is a curve with a hump. If this is the case, we only need to choose a motor with a rated power slightly higher than the power value of the hump point. Then, in the entire range from 0 flow to maximum flow, no matter which operating point you run at, the pump power will not exceed the motor power and cause the pump to be overloaded. For pumps with this performance, both selection and use will be very convenient and reliable.

If the self-priming sewage pump is in a building, the site is small, and the drainage volume is not large, self-priming sewage pumps and submersible sewage pumps can be used first. Among them, submersible sewage pumps can generally be used in more important places. Its overall structure is compact, small in size, low in noise, easy to move, and simple to install. The energy-saving effect is remarkable, and the maintenance is convenient. There is no need to build a pump room, and it can be submerged in the water, which greatly reduces the project cost. In public buildings and facilities, a spare water pump should be set up according to each drainage and water collection tank as a unit. It is advisable to operate alternately at ordinary times to reduce the long-term load operation of the pump and increase its service life. When extracting sewage with large media, the outlet pipes of the self-priming sewage pumps in different water collection tanks should not be combined for discharge, and the self-priming sewage pump is best equipped with a crushing device. When lifting sewage containing more fiber, the self-priming sewage pump can use a cutting device or a large-channel self-priming sewage pump. When extracting general wastewater, the outlet pipes of the self-priming sewage pumps in different water collection tanks can be combined for discharge according to actual conditions. When two or more water pumps share a water outlet pipe, valves and check valves should be installed on the outlet pipes of each water pump. When a single water pump may cause backflow when draining, a check valve should be installed. It is not allowed to combine the pressure drainage valve with the gravity drainage pipe in the building for discharge.

The self-priming sewage pump adopts a unique structure and a new type of mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of this pump adopts a single-channel or double-channel form. It is similar to a curved pipe with the same cross-section size and has very good flow properties. With a reasonable volute chamber, the pump has high efficiency. The impeller has been tested for dynamic and static balance, so that the pump has no vibration during operation.