Maintenance Tips For Sanitary Centrifugal Pumps

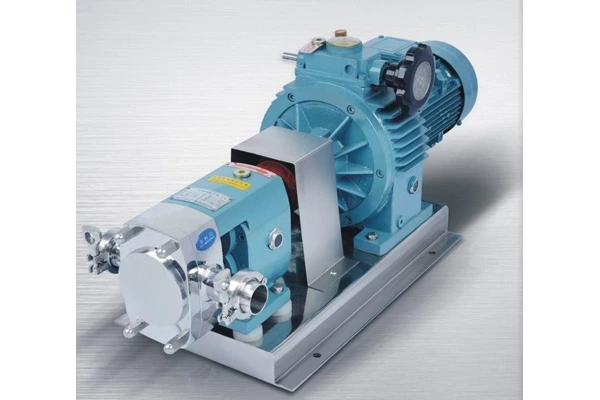

Sanitary Centrifugal Pump mainly includes inlet pipes, one-way valves, outlet pipes, pump bodies, impellers, mechanical seals, bearing seats and pump shafts. The double-blade impeller structure is adopted to improve the passage capacity of dirt. The mechanical seal adopts a new friction pair and runs in the oil chamber for a long time. It has compact structure, small size, low noise, significant energy saving effect, and easy maintenance and replacement. The automatic control cabinet can automatically control the start and stop of the pump according to the required changes without the need for special supervision, and is easy to use. The installation method can be equipped according to the user's needs, and people do not need to enter the sewage pit during installation. It can be used within the design range to ensure that the motor is not overloaded. The pump is equipped with an outdoor motor, so there is no need to build a pump room and can be directly installed outdoors for use.

Comprehensive maintenance tips for sanitary centrifugal pumps:

The first is the direction. Regularly check whether any parts are abnormal. If there are any abnormalities, check the instructions or other information and replace the parts if necessary. Check whether there is any looseness in the self-priming pump pipeline and joints. Turn the self-priming pump with your hands or tools to see if the sanitary centrifugal pump is flexible.

Second, try to control the flow and head of the self-priming pump within the range indicated on the sign to ensure that the self-priming pump operates at the highest efficiency point to achieve the greatest energy saving effect.

Third, during the operation of the self-priming pump, the bearing temperature must not exceed the ambient temperature of 35C, and the maximum temperature must not exceed 80C.

Fourth, if you find that the self-priming pump has abnormal sounds, you should stop the vehicle immediately to check the cause.

Fifth, when the sanitary centrifugal pump is to be stopped, first close the gate valve and pressure gauge, and then stop the motor.

Sixth, when the sanitary centrifugal pump is not used for a long time or is used in cold winter, after parking, it is necessary to unscrew the drain plug at the bottom of the pump body and drain the medium. Prevent freezing cracking (if it is sewage, please clean the pump cavity with clean water).

Seventh, when the sanitary centrifugal pump is not used for a long time, it should be cleaned, hoisted and placed in a ventilated and dry place, and pay attention to anti-freeze. If placed in water, run it for at least 30 minutes every 15 days (no dry grinding) to check its function and adaptability.

Eighth, cables should be inspected at least once a year and replaced if damaged.

Ninth, listen carefully to whether the running sound of the motor is abnormal. Because the noise in the room is loud when running, you can use auxiliary tools such as screwdrivers or listening sticks to listen close to both ends of the motor. If you listen often, you can not only find the motor and its drag The bad vibration of the moving equipment can even be judged by the amount of internal bearing oil, so that corresponding measures such as adding bearing oil or replacing new bearings can be taken promptly to avoid dry wear of the motor bearings due to lack of oil, stalling, cylindrical movement, and bore sweeping. Burned out.

Tenth, after a malfunction occurs in the operation of the sanitary centrifugal pump, please follow the troubleshooting methods given. If it still cannot be solved and the cause cannot be determined, do not dismantle or repair it without permission. You should find a dedicated person for repair immediately.

Sanitary centrifugal pumps can be widely used in municipal sewage projects, light industry, papermaking, textiles, food, chemical industry, electricity, petroleum, mining and river pond breeding and other industries. Sanitary centrifugal pump is currently the most ideal impurity pump in China for pumping solid particles, fibers, slurries and mixed suspension media.