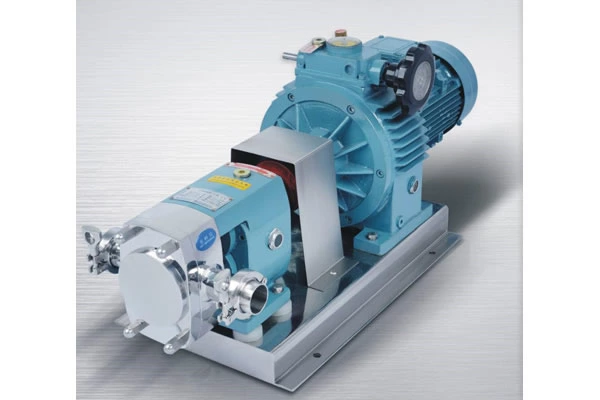

Introduction Of Sanitary Rotary Lobe Pump

Sanitary Rotary Lobe Pump, specifically, a sanitary rotary cam pump with acid and wear resistance. According to the design scheme provided by the utility model, the driving shaft and the driven shaft are installed on the housing, the gear is installed on a section of the driving shaft located in the housing, and the gear meshing with the gear is installed on the driven shaft to form a pair of gear pairs, and the inlet and outlet of the material are set on the housing. The characteristic is that a ceramic plate is set on the inner wall of the cavity accommodating the gear pair in the housing. This device improves the acid and wear resistance of the sanitary rotary cam pump by changing the structure of the sanitary rotary cam pump.

It is mainly used in water systems with small flow and high lift, such as drinking water supply systems, pressure boiler water supply systems, high-purity water purification systems, and flushing, spraying and other processes in the pharmaceutical, food, fine chemical, papermaking and other industries.

Structural features of sanitary rotary cam pump

1. Sliding bearings

The materials of the sliding bearings of sanitary rotary cam pumps include impregnated graphite, filled polytetrafluoroethylene, engineering ceramics, etc. Since engineering ceramics have good heat resistance, corrosion resistance and friction resistance, the sliding bearings of sanitary rotary cam pumps are mostly made of engineering ceramics. Since engineering ceramics are very brittle and have a small expansion coefficient, the bearing clearance must not be too small to avoid shaft seizure accidents. Since the sliding bearings of sanitary rotary cam pumps are lubricated with the medium being transported, different materials should be selected to make bearings according to different media and working conditions.

2. Isolation sleeve

When a metal isolation sleeve is used, the isolation sleeve is in a sinusoidal alternating magnetic field, and eddy currents are induced on the cross section perpendicular to the direction of the magnetic lines of force and converted into heat. The expression of eddy current is: Where Pe-eddy current; K-constant; n-rated speed of the pump; T-magnetic transmission torque; F-pressure in the spacer sleeve; D-inner diameter of the spacer sleeve; -Resistivity of the material; -tensile strength of the material. When the pump is designed, n and T are given by the working conditions. To reduce the eddy current, only F and D can be considered. The use of non-metallic materials with high resistivity and high strength to make isolation sleeves is very effective in reducing eddy currents.3. Control of cooling and lubricating liquid flow

When the sanitary rotary cam pump is running, a small amount of liquid must be used to flush and cool the annular gap area between the inner magnetic rotor and the isolation sleeve and the friction pair of the sliding bearing. The flow rate of the coolant is usually 2%-3% of the pump design flow rate. The annular gap area between the inner magnetic rotor and the isolation sleeve generates high heat due to eddy currents. When the cooling and lubricating liquid is insufficient or the flushing hole is blocked, the medium temperature will be higher than the working temperature of the permanent magnet, causing the inner magnetic rotor to gradually lose its magnetism and the magnetic transmission to fail. When the medium is water or water-based liquid, the temperature rise in the annular gap area can be maintained at 3-5°C; when the medium is hydrocarbon or oil, the temperature rise in the annular gap area can be maintained at 5-8°C.