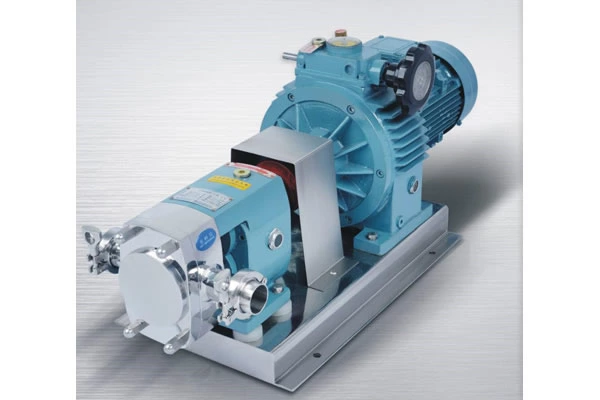

Improvement Of The Structural Design Of Sanitary Rotary Lobe Pump

Regarding Sanitary Rotary Lobe Pump, most domestic manufacturers now produce submersible screw pumps, that is, the impeller is improved on the basis of the open impeller of the submersible sewage pump. Most of the applications are for submersible sewage treatment. The sanitary rotary cam pump produced by the company has made a further technical improvement on the original pump, using a shaft-connected connection method, and has a wider range of applications. Features: The sanitary rotary cam pump was successfully researched by the Peruvian government in the 1960s. It was originally used to catch fish and shrimp, and then used to transport solid-liquid mixtures; two-phase flow, it can also be used to drain and transport liquids with high mixing ratios and not too viscous. In order to prevent solid substances from blocking the conveying medium and making it flow out smoothly, a twisted spiral blade is provided in the impeller, and it is extended axially from the suction port on the conical hub body. The radius of the blade gradually increases to form a spiral fluid channel. The shell consists of two parts: a conical suction cover and a volute. The suction cover part of the impeller. Like a propeller, it produces a spiral propulsion effect. The impeller of the volute part produces a centrifugal effect like a general centrifugal pump. The sharp angle of the blade inlet guides the debris to the vicinity of the axis, and then uses the spiral action to propel it along the axis. This combination of a volumetric pump and a centrifugal pump is called a sanitary rotary cam pump.

Features

1. Smooth and gentle delivery, energy saving.

2. Good non-clogging performance, can deliver particles and fiber-containing materials

3. Good non-stirring and non-destructive performance, can deliver water-mixed materials such as fish, shrimp, and fruits.

4. Suitable for conveying pulp and cotton pulp with a concentration of 1-12%, which has been widely used abroad.

5. The pump has a simple structure and is easy to maintain.

6. The power is transmitted by a pulley, and the technical parameters of the pump are highly variable, and the effect is more obvious when a variable frequency motor is used.

Installation and use

Before installing the equipment, the foundation must be checked according to the equipment foundation diagram and the actual object to confirm that the equipment foundation is correct. The pump body is generally made of stainless steel 304 and stainless steel 316, which is more suitable for applications with certain corrosion or food, aquatic fishery occasions.

Scope of application

Sewage treatment: discharge of high-concentration untreated sewage and dirt, such as the test of larger-caliber pumps conveying plastic woven belts up to 1 meter long;

River dredging: conveying silt and sand;

Papermaking: conveying high-concentration pulp;

Marine fishing: conveying live fish, live shrimp, etc.;

Food processing industry: conveying block vegetables such as potatoes and beets.