Important Characteristics Of Cip Return Pumps

The flow rate of CIP Return Pump is mostly selected between 0.5LS-2.0LS. When the system has no air pressure tank, there will be water hammer when the pump is stopped. In view of the requirements of the monitoring and automatic control functions of the system for the CIP return pump, we recommend that the flow rate of the CIP return pump be 1.0LS-2.0LS, and the pressure be 0.1Mpa-2.0Mpa higher than the main pump or 1.1 times-1.2 times that of the main pump. It is best to have an air pressure tank with a CIP return pump. If there is no air pressure tank, the controller of the CIP return pump should be modified so that it will not start frequently due to water hammer when the pump is stopped.

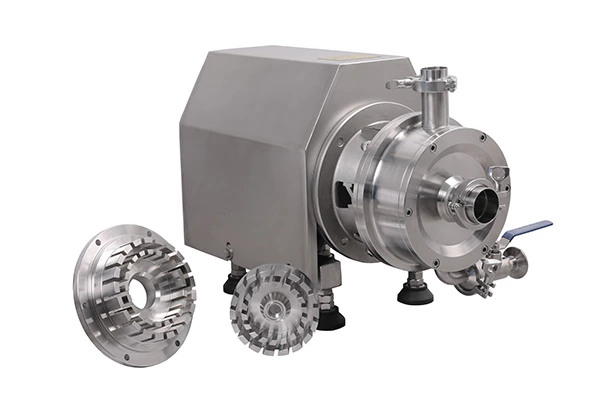

The CIP return pump is used to transport clean water without solid particles and liquids with physical and chemical properties similar to water. The flow range of the conveyed liquid is 5-80L/S, the pressure range is 0.2-2.25Mpa, the supporting power range is 1.5-200KW, and the caliber range is φ50-φ200m. The CIP reflux pump uses a wear-resistant mechanical seal for the pump seal, which is leak-free and has a long service life. The CIP reflux pump uses hydraulic balance to solve the axial force, so the pump runs smoothly and has low noise. The installation conditions are better than the CIP reflux pump, and it can be easily installed in the middle of any horizontal pipeline.

Important features of the CIP reflux pump:

a. The pump has a compact structure, small size, and beautiful shape. Its horizontal structure occupies a small area when installed, and its center of gravity coincides with the center of the pump foot, thereby enhancing the running stability and service life of the pump.

b. The suction and discharge ports of the CIP reflux pump are both horizontally oriented, which simplifies the connection of the pipeline.

c. The multi-stage type can be installed in the same direction or in different directions of 90°, 180°, and 270° according to needs to meet different connection locations.

d. The pressure of CIP return pump can be satisfied by increasing or decreasing the number of pump stages and cutting the outer diameter of the impeller according to the needs, without changing the installation footprint, which is not available in other pumps.

CIP return pump is mainly used for pressurized water delivery in fire protection system pipelines. It can also be used in industrial and urban water supply and drainage, high-rise building pressurized water delivery, long-distance water delivery, heating, bathroom, boiler hot and cold water circulation pressurized air conditioning refrigeration system water delivery and equipment matching.