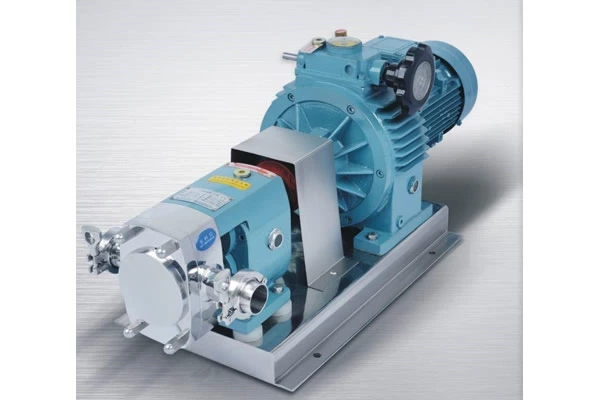

How To Use Sanitary Rotary Lobe Pump Correctly

Undoubtedly, there will always be problems with the machine during use, but good use and maintenance can ensure the best performance of the machine. In order to ensure normal oil supply, the normal use and rapid maintenance of Sanitary Rotary Lobe Pump have become the top priority of oil depot equipment management.

Test run: Check whether the connecting parts are loose; turn the coupling by hand to make the rotor rotate several times to see whether the unit rotates flexibly, whether there is sound and uneven feeling, to judge whether there are foreign objects in the pump or whether the shaft is bent, whether the seal is installed correctly, etc.; check whether the clean No. 20 lubricating oil in the sealing chamber is filled with 1/2 of the cavity space; whether the surface of the pump unit is clean; the unit turns to no-load test.

Operation inspection: When the sanitary rotary cam pump is operating normally at power frequency (variable frequency), the readings of the pump unit's ammeter, voltmeter, inlet and outlet vacuum gauge, pressure gauge and flow meter should be checked and recorded regularly. Whether the vibration, noise, temperature rise, etc. of the unit are normal. There should be no obvious aviation oil leakage at the shaft seal.

In addition, we have to consider parking, which mainly has two types

Emergency parking conditions:

⑴ The pump motor working current meter indicates abnormality (too large or too little); the pump system makes abnormal noises.

⑵ The pump inlet vacuum pressure gauge and outlet pressure gauge indicate abnormality, the pump body vibrates greatly and makes abnormal noises, and the performance is seriously reduced.

⑶ The pump motor produces odor, aviation oil leaks from the shaft seal, and the bearing temperature exceeds 75 degrees.

Normal parking: close the discharge valve, lightly load the pump, and stop the motor.