How To Solve The Problems We Encounter When Using Metering Pumps

1) Abnormal liquid suction of metering pump

Rotating to the position of 100% length can make the discharge hole of the whole system component of the enterprise and the bottom data of the pump present the state of alignment.

For the reaction time, the continuous development of the pulse may not be long enough. Relative to the pulse signal width of the national standard, the continuous expansion of the flow monitor pulse width can be activated, which can increase a pulse width.

The pump head of the metering pump adopts self-priming filling to shorten the suction pipeline as much as possible.

2) Replacing the diaphragm of the metering pump

We often encounter problems when removing the old diaphragm. There are several points to note about how to remove the old diaphragm:

1. When the pump head is loose, adjust the stroke length to 10% before removing the pump head. It can ensure that the electromagnetic shaft has enough pressure and maintain the stability of its connection.

Pull the hydraulic end outward to disengage the screw from the socket. Grasp the liquid end of the development and rotate it counterclockwise. With a little resistance, the diaphragm can be loosened.

⒊ The medicine in the metering process may crystallize at the hydraulic end, causing some components to fail to work properly.

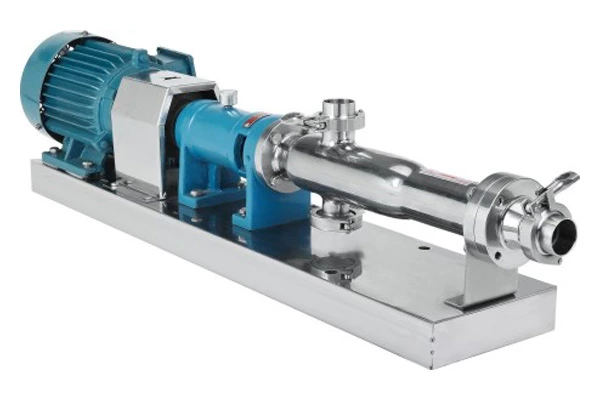

There may be gas leakage at the suction end of Emulsification Pump. There may be looseness between the connections on the suction side of the hydraulic end.