How To Solve The Leakage Problem Of Mechanical Seals In Pipeline Pumps, Sewage Pumps And Centrifugal Pumps

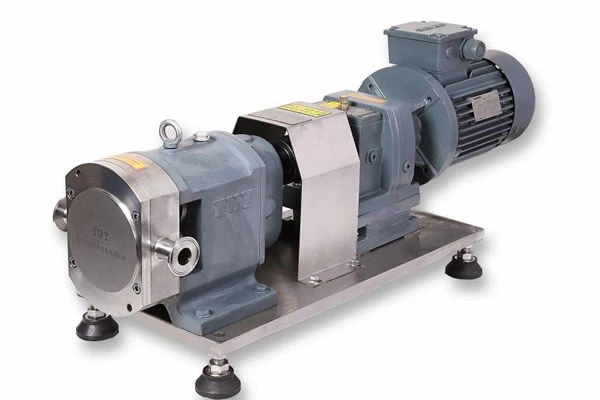

Pipeline pump, sewage pump, Sanitary Rotary Lobe Pump mechanical seal periodic leakage

(1) The axial movement of the pump rotor is large, the interference between the auxiliary seal and the shaft is large, and the dynamic ring cannot move flexibly on the shaft. When the pump is turned over and the dynamic and static rings are worn, the displacement cannot be compensated.

Countermeasures: When assembling the mechanical seal, the axial movement of the shaft should be less than 0.1mm, and the interference between the auxiliary seal and the shaft should be moderate. While ensuring radial sealing, the dynamic ring can be ensured to move flexibly on the shaft after assembly.

(2) Insufficient lubricating oil on the sealing surface causes dry friction or roughening of the sealing end surface.

Countermeasures: The height of the lubricating oil level in the oil chamber cavity should be added to be higher than the dynamic and static ring sealing surfaces.

(3) The rotor vibrates periodically. The reason is that the stator is not aligned with the upper and lower end covers or the impeller and the main shaft are unbalanced, cavitation or bearing damage, which will shorten the seal life and cause leakage.

Countermeasures: The above problems can be corrected according to the maintenance standards.