How To Select Fluoroplastic Magnetic Pump

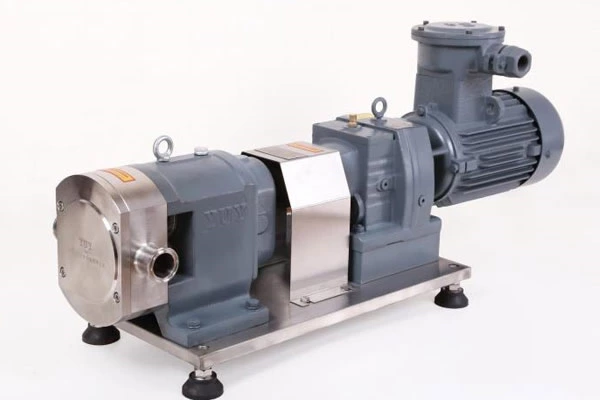

Sanitary Rotary Lobe Pump consists of three parts: gear pump, magnetic transmission and motor. It is a common pump in the market now, which can be widely used in petroleum, chemical industry, pharmaceutical industry, electroplating, printing and dyeing, food, scientific research, etc. The following is the selection principle of fluoroplastic magnetic pump introduced by the editor.

In the market, there are many types of magnetic pumps. Determining the purpose and performance parameters of the pump and selecting the pump type are the key points in the design of the entire device. The selection principles of fluoroplastic magnetic pumps are as follows:

1. For pumps that transport corrosive media, the convection parts are required to be made of corrosion-resistant materials, such as fluoroplastic corrosion-resistant pumps.

2. For pumps that transport flammable, explosive, toxic or precious media, the shaft seal is required to be reliable or a leak-free pump is used, such as a magnetic drive pump (no shaft seal, using isolated magnetic indirect drive).

3. For pumps that transport media containing solid particles, the convection parts are required to be made of wear-resistant materials, and the shaft seal is flushed with clean liquid when necessary.

4. Make the type and performance of the selected pump meet the requirements of process parameters such as device flow, head, pressure, temperature, cavitation margin, suction head, etc.

5. The mechanical requirements are high reliability, low noise and low vibration.

6. It is necessary to clearly calculate the input cost of pump procurement and also to inspect the manufacturer, requiring its equipment quality, good after-sales service, and timely supply of spare parts. This is a must for every purchasing staff.