How To Calculate The Power Of The Water Pump

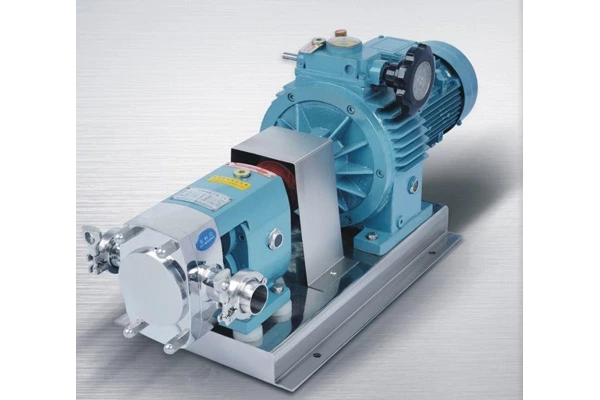

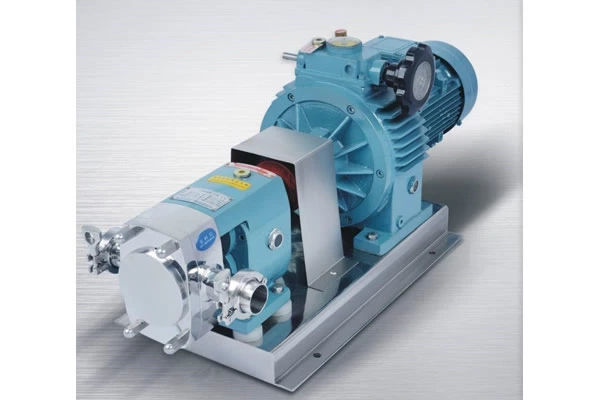

What is the power of Sanitary Rotary Lobe Pump?

Power refers to the amount of work done by the pump per unit time, represented by the symbol N. Common units are: kg·m/s, kilowatt, horsepower. The power unit of the motor of the power equipment is expressed in kilowatt, and the power unit of the diesel engine or gasoline engine is expressed in horsepower.

What is the effective power of the pump?

Effective power is also called output power, represented by Pe, which is the effective energy obtained in the pump by the medium liquid output from the pump per unit time.

Head refers to the energy obtained from the pump by the unit weight of liquid output by the pump, so the head refers to the effective energy obtained from the liquid output by the pump per unit time - that is, the effective power of the pump:

The equation is Pe=ρgQH(W)=γQH(W)

Where ρ——density of the conveying medium liquid (kg/m3);

γ——heavyness of the conveying medium liquid (N/m3);

Q——water pump flow (m3/s);

H——water pump head (m);

g——gravitational acceleration (m/s2).

The difference between shaft power P and effective power Pe is the power loss in the pump, and its size is measured by the efficiency of the pump. The efficiency of the pump is the ratio of effective power to shaft power, expressed as η.

The more medium liquid the water pump outputs, the more work it does. The less water it sends out, the less work it does, and the current is reduced accordingly. Water pump power (KW) = head (m) × flow rate (m3/s) × fluid weight (water takes 1000kg/m3) ÷ 102 (power conversion coefficient) ÷ pump efficiency (about 70%), and motor power P = I × U to express, the larger the power, the larger the current.

Due to the friction resistance of the bearing and filler; the friction between the impeller and the water when it rotates; the vortex, gap backflow, inlet and outlet, and mouth impact of the water flow in the pump. It is inevitable that part of the power is consumed, so the water pump cannot completely convert the power input by the power machine into effective power, and there must be power loss, so the shaft power = effective power + loss power.

Water pump power calculation formula?

Centrifugal pump power calculation formula

Flow rate × head × 9.81 × medium specific gravity ÷ 3600 ÷ pump efficiency;

Flow rate unit: cubic / hour, head unit: meter;

P = 2.73HQ / η;

Where H is the head, unit m, Q is the flow rate, unit m3 / h, η is the pump efficiency, P is the shaft power, unit KW, that is, the pump shaft power P = ρgQH / 1000η (kw), where ρ = 1000Kg / m3, g = 9.8;

The unit of specific gravity is Kg / m3, the unit of flow is m3 / h, the unit of head is m, 1Kg = 9.8 Newton;

Then P = specific gravity * flow * head * 9.8 Newton / Kg;

= Kg / m3 * m3 / h * m * 9.8 Newton / Kg;

=9.8 Newton*m/3600 seconds;

=Newton*m/367 seconds;

=Watt/367.

The above derivation is the origin of the unit. The above formula is the calculation of water power. The shaft power is divided by the efficiency to get it. Let the shaft power be Ne, the motor power be P, and K be the coefficient (the inverse of efficiency)

Motor power P=Ne*K (K has different values when Ne is different, see below)

Ne≤22 K=1.25 22 55

Through the derivation of the above formula, we can know the following situations:

1. Regardless of the manufacturer, when the flow rate and head are determined, the actual effective power is fixed;

2. The power consumption of the water pump does not depend on the motor power of the water pump, but on the shaft power of the water pump. The same is equipped with a 30kw motor. The shaft power of one is 20.56kw and the other is 25.18kw. Obviously, 20.56kw is more energy-saving, and the key to the size of the shaft power is the efficiency of the water pump.