How Does The Self-priming Oil Pump Ensure The Safety Of Users?

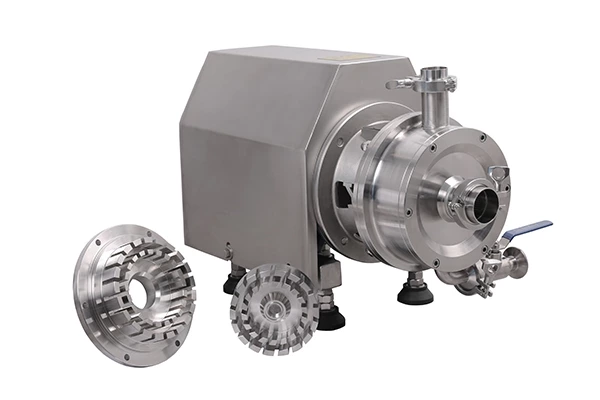

Emulsification Pump all adopt the pump body structure of axial liquid return. The pump body consists of suction chamber, liquid storage chamber, vortex chamber, liquid return hole, gas-liquid separation chamber, etc. After the pump starts normally, the impeller sucks the liquid stored in the suction chamber and the air in the suction pipe together, and they are completely mixed in the impeller. Under the action of centrifugal force, the liquid carries the gas to the outer edge of the vortex chamber, forming a white foam belt with a certain thickness and a high-speed rotating liquid ring on the outer edge of the impeller. The gas-liquid mixture enters the gas-liquid separation chamber through the diffusion tube. At this time, due to the sudden decrease in flow rate, the lighter gas is separated from the mixed gas and liquid, and the gas continues to rise and discharge through the pump body outlet. The degassed liquid returns to the liquid storage chamber and enters the impeller again through the reflux hole, and mixes again with the gas sucked from the suction pipe inside the wheel. Under the action of the high-speed rotating impeller, it flows to the outer edge of the impeller... As this process goes on repeatedly, the air sucked into the tubes and feet continues to decrease until the gas is completely sucked out, the self-priming process is completed, and the pump is put into normal operation. Because the cyz-a self-priming oil pump has this unique exhaust capacity, this pump can transport liquids containing gas without installing a bottom valve, and has a good tank sweeping function when used on tankers.

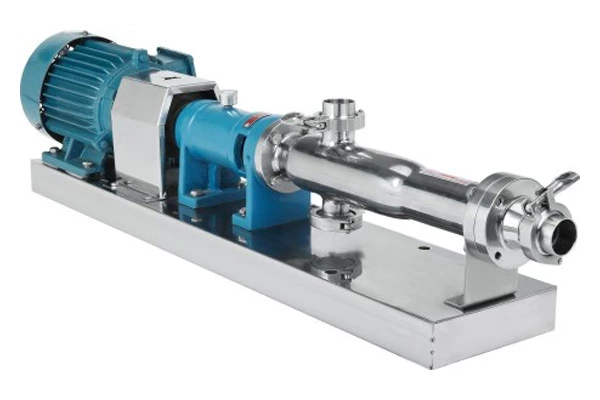

Self-priming oil pumps are widely used in oil depots, gas stations, tankers, oil tankers, docks, oil trucks, airports, and transport gasoline, kerosene, diesel, aviation kerosene, etc. If corrosion-resistant mechanical seals and stainless steel materials are used, they can also be used in chemical, pharmaceutical, brewing, electroplating, printing, papermaking, power mining, etc. The conveying medium temperature is -20℃-80℃, the viscosity is ≤100 centipoise, and the solid content can reach less than 30%. The cyz-a self-priming oil pump is particularly suitable for tankers or water transport ships, and can also be used as a tank sweeping pump with good tank sweeping effect.

Self-priming oil pump product features:

1. It has the characteristics of simple structure, convenient operation, stable operation, easy maintenance, high efficiency, long life, and self-priming function that other pumps do not have. No bottom valve is required in the pipeline. Before working, it is only necessary to ensure that there is a certain amount of priming oil stored in the pump body. It has the function of "one drainage, lifelong self-priming". When used for oil tankers or marine oil pumps, it can also be used as a tank sweeping pump with good tank sweeping effect.

2. It is made of high-quality materials and the seal adopts carbide mechanical seal, which is durable. The discharge pipeline does not need to be installed with a safety valve, and the suction pipeline does not need to be installed with a bottom valve. Therefore, the pipeline system is simplified and the working conditions are improved.

3. The self-priming oil pump adopts a copper impeller, oil-resistant mechanical seal and explosion-proof motor, which is more suitable for conveying oil products and protecting the life and property of users.

The self-priming oil pump is the latest product developed based on digestion, absorption and improvement of relevant domestic and foreign technical information. This pump is an ideal product for the petroleum industry, land oil depots, and oil tankers. It is also suitable for use as a ship cargo oil pump, bilge pump and ballast pump, and machine cooling water circulation, etc. It can transport petroleum products such as gasoline, kerosene, diesel, aviation kerosene, and seawater and clean water, respectively. The medium temperature is -20℃-80℃. If corrosion-resistant mechanical seals and stainless steel materials are used, it can also be used in chemical, pharmaceutical, brewing, electroplating, printing and dyeing, papermaking, electric power, mining, etc. It is a high-efficiency and energy-saving oil pump.