Five Common Faults During The Use Of Sanitary Rotary Lobe Pumps

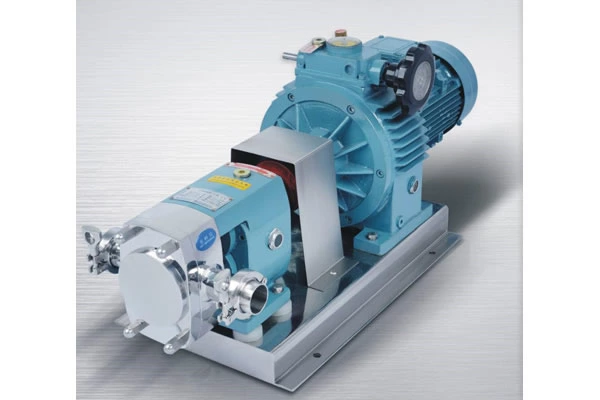

Sanitary Rotary Lobe Pump is mainly composed of pump head, magnetic transmission, motor and connecting plate. It is widely used in many industries. However, during the use of sanitary rotary cam pump, it often encounters faults that cause the pump to fail to operate normally. The following editor summarizes five common faults.

1. Bearing damage. The bearing of the sanitary rotary cam pump is made of high-density carbon. If the pump is cut off or there are impurities in the pump, the bearing will be damaged. If the coaxiality requirements between the inner and outer magnetic rotors of the cylindrical coupling are not guaranteed, it will directly affect the life of the bearing.

2. Insufficient head. The causes of this fault are: air in the conveying medium, impeller damage, insufficient speed, excessive specific gravity of the conveying liquid, and excessive flow rate.

3. Shaft breakage. The pump shaft of the sanitary rotary cam pump is made of 99% alumina porcelain. The main reason for the pump shaft breakage is that the pump is running empty and the bearing is dry-grinded and the shaft is twisted off. When the pump is disassembled for inspection, it can be seen that the bearing is severely worn. The main way to prevent the pump from breaking is to avoid the empty running of the pump.

4. Insufficient flow. The main reasons for insufficient flow are: impeller damage, insufficient speed, too high head, debris blocking the pipe, etc.

5. Failure to pump out liquid. The failure of a sanitary rotary cam pump to pump out liquid is the most common failure of the pump, and there are many reasons for it. First, check whether there is a leak in the suction pipe of the pump, check whether the air in the suction pipe is discharged, whether the amount of liquid poured into the sanitary rotary cam pump is sufficient, whether there is debris blocking the suction pipe, and whether the pump is reversed (especially after the motor is replaced or the power supply line is overhauled). Also pay attention to whether the suction height of the pump is too high. If the above inspections still cannot solve the problem, the pump can be disassembled and checked to see if the pump shaft is broken. It should also be checked whether the dynamic ring and static ring of the pump are intact, and whether the entire rotor can move axially in a small amount. If axial movement is difficult, check whether the carbon bearing is too tightly combined with the pump shaft.