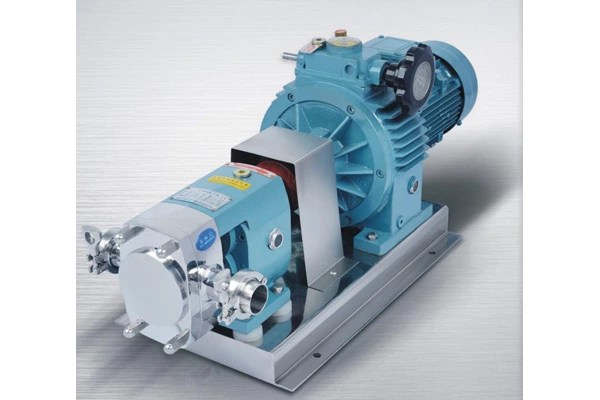

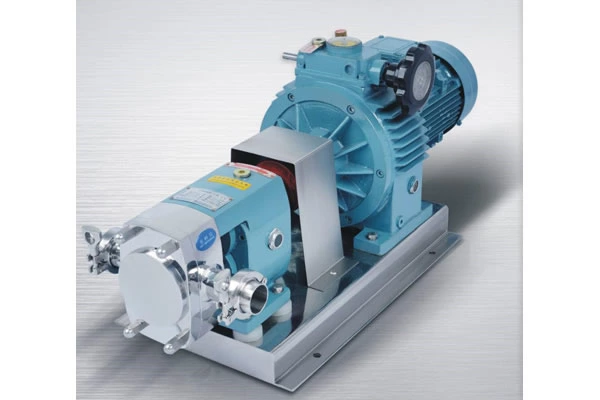

Fault Diagnosis And Troubleshooting Of Sanitary Rotary Lobe Pumps

Sanitary Rotary Lobe Pump is a sanitary rotary cam pump that relies on the change and movement of the working volume formed between the pump cylinder and the meshing gears to transport liquid or increase its pressure. It consists of two closed spaces, two gears, a pump body, and front and rear covers. When the gears rotate, the volume of the space on the gear disengagement side changes from small to large, forming a vacuum, sucking the liquid in, and the volume of the space on the gear meshing side changes from large to small, squeezing the liquid into the pipeline. The suction chamber and the discharge chamber are separated by the meshing line of the two gears. The pressure of the discharge port of the sanitary rotary cam pump depends entirely on the size of the resistance at the pump outlet.

1. Severe vibration and noise generated by sanitary rotary cam pumps

1) Caused by poor sealing. Solution: Repair the plane of the pump body and the pump cover (0.005).

2) The skeleton seal on the pump shaft is aging. Solution: Replace.

3) There is less oil in the oil tank and the pump sucks empty. Solution: Add oil.

4) The return oil pipe is exposed to the liquid surface, and the instantaneous negative pressure causes the air to backflow into the system. Solution: It should be inserted under the liquid.

5) The pump is too high from the liquid surface. At low speed, the pump oil chamber cannot be vacuumed and air is sucked in. Solution: Try to shorten the relative distance.

6) The oil inlet resistance is large or the oil inlet pipe is too large to enter the air. Solution: Clean the filter or increase the filtration volume or reduce the pipe diameter.

2. Vibration and noise caused by mechanical reasons

1) The coaxiality of the pump and the coupling.

2) The noise caused by the wear and tear of the gears of the sanitary rotary cam pump, replace the oil and strengthen the filtration. Solution: Clean the pump or replace the pump.

3) The needle bearing in the pump is not smooth. Solution: Replace the bearing.

3. Vibration and noise caused by other reasons

1) The oil inlet filter is blocked. Solution: Clean the filter.

2) The oil viscosity is high and produces noise. Solution: Choose a reasonable oil.

3) The oil inlet and outlet apertures are too large to produce noise. Solution: Appropriately reduce the pipe diameter.

4. The output flow of the sanitary rotary cam pump is insufficient and the pressure cannot be increased

1) The oil inlet is blocked and the air is sucked and the flow is insufficient. Solution: Clean the filter.

2) The pump has large internal leakage and small flow. Solution: Repair the mold cover and gear end face or replace the pump.

3) The oil temperature is too high, the internal leakage is large and the output flow is small. Solution: Add oil and cool the machine.

4) The oil viscosity is too high, the oil absorption resistance is large or the viscosity is too low, and the internal leakage is large. Solution: Choose a suitable hydraulic oil. Generally 32 (40 degrees)