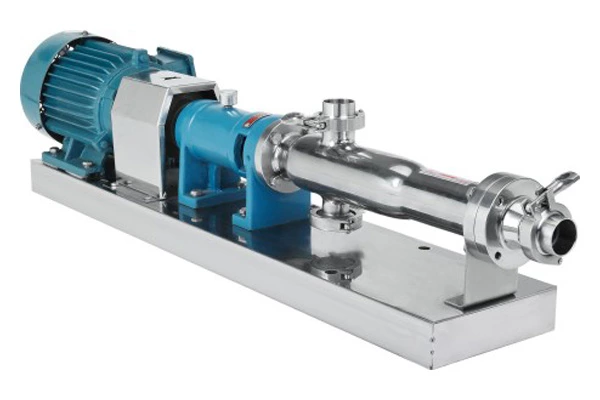

Emulsification Pump Is A Safe And Reliable Companion For All Kinds Of Water Pumps

Emulsification Pump should be managed and used by a dedicated person, and the circuit and pump of the water pump should be checked regularly to see if they are working properly. After each use, especially for viscous slurries, the water pump should be placed in clean water and run for several minutes to prevent sediment from being left in the pump. The oil in the oil chamber should be filled or replaced after 300-500 hours of use to keep the mechanical seal in a good lubrication state and increase the service life of the mechanical seal. The sealing ring between the impeller and the pump body has a sealing function. If the sealing ring fails, it should be replaced in time to avoid affecting the normal operation of the emulsification pump. The emulsification pump is suitable for the discharge of seriously polluted wastewater from factories and commerce, sewage discharge stations in main residential areas, water distribution systems of urban sewage treatment plants, drainage stations of civil air defense systems, water supply equipment of water plants, sewage discharge from hospitals and hotels, municipal engineering construction sites, supporting machines of mines, rural biogas pools, farmland irrigation and other industries, conveying sewage and dirt with particles, and can also be used for clean water and weakly corrosive media.

The emulsification pump can meet the requirements of use in high head occasions. Because the mechanical seal is operated in a negative pressure state, it has higher stability. The double-down water absorption structure has a low water absorption level. Because the double-suction double-flow channel single volute structure is adopted, the motor has no axial tension. The emulsification pump reduces and balances the radial force, greatly increasing the service life of the pump by 3 times and improving the use efficiency by 15%.

The sewage treatment pump station using the emulsification pump dedicated intelligent protection control cabinet can use the intermediate terminal box to separate the pump room and the control room, and can also be installed outdoors without the pump room. Therefore, the ventilation and lighting conditions of the control room can be greatly improved. In addition, the application of the fully automatic control cabinet makes the starting process of the emulsification pump very simple, and the operable procedures for starting and stopping the emulsification pump are also greatly simplified. The system runs safely and reliably, and the control is flexible and free. Since the DC current signal can be used between the intermediate terminal box and the control cabinet, it can be transported over long distances without attenuation, which facilitates the realization of long-distance unmanned management and automated operation monitoring.

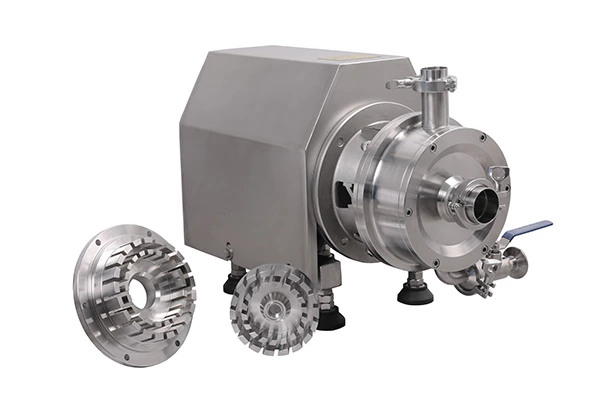

The emulsification pump adopts a unique impeller structure and a new mechanical seal, which can effectively transport solids and long fibers. Compared with the traditional impeller, the impeller of this pump adopts a single-channel or double-channel form. It is similar to a curved pipe with the same cross-section size, has very good flowability, and is equipped with a reasonable volute chamber, which makes the pump highly efficient. The impeller has been tested for dynamic and static balance, and the emulsified pump has no vibration during operation.

Emulsified pumps can be widely used in industrial and agricultural production and various types of buildings for water supply, drainage, fire protection, sprinkler network boosting, and HVAC hot and cold water circulation and other occasions for automatic control. The emulsified pump control cabinet has excellent internal quality, beautiful and durable appearance, and is easy to install and operate. It is a safe and reliable companion for various water pumps.