Design Concept And Application Scope Of Sanitary Rotary Lobe Pump

Sanitary Rotary Lobe Pump Introduction

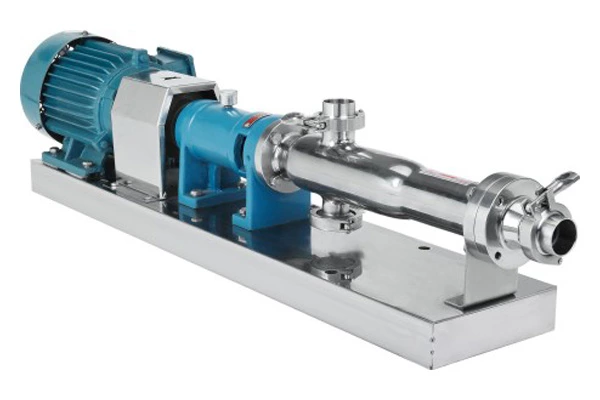

The sanitary rotary cam pump is mainly composed of gears, shafts, pump bodies, safety valves, and shaft end seals. The gears have high hardness and strength after heat treatment, and are installed together with the shaft in a replaceable sleeve for operation. The lubrication of all parts in the pump is automatically achieved by using the output medium when the pump is working.

The sanitary rotary cam pump has a well-designed oil drain and return oil groove, which minimizes the torque force borne by the gears during operation, so the bearing load is small, the wear is small, and the pump efficiency is high. The pump is equipped with a safety valve as an overload protection. The full return pressure of the safety valve is 1.5 times the rated discharge pressure of the pump, and it can also be adjusted according to actual needs within the allowable discharge pressure range. However, please note that this safety valve cannot work as a pressure reducing valve for a long time, and it can be installed separately on the pipeline when necessary.

Scope of application of sanitary rotary cam pump

It is mainly used for large-flow oil transportation and unloading in oil fields, oil depots, ports, docks, ships, etc.!

Design concept of sanitary rotary cam pump

The selection of materials for the manufacture and processing of sanitary rotary cam pumps is very important in the selection of high-temperature industrial pumps. Sanitary rotary cam pumps are often used to transport highly corrosive, abrasive or volatile fluids. The materials of the pump housing, shaft and bearings must first match the pumped liquid. When high temperatures are considered, the design of sanitary rotary cam pumps becomes more complicated, and even the thermal expansion of various materials needs to be considered. Sanitary rotary cam pumps need to consider different quality factors in use, play an important role in value and performance, and ensure that they can play an important role in the industry.

Preheating of sanitary rotary cam pumps is necessary to avoid damage to components caused by high temperature shock. Preheating is recommended when the pumped fluid temperature is higher than 150°C. When using mechanical seals, sanitary rotary cam pumps need to be preheated to within 30°C of the operating temperature difference to prevent damage to the sealing surface. Jacketed pumps can be preheated by steam, heat medium and electric heating. Viscosity is the resistance to fluid flow. The first problem in high viscosity conditions is how to get the fluid into the pump. The sanitary rotary cam pump must rotate very slowly to allow the fluid to enter the cavity between the unmeshed teeth, which forms a suction force to draw the fluid into the pump. The tighter the clearance, the better the internal seal of the sanitary rotary lobe pump and the stronger the suction.