Complete Methods For Water Pump Anti-cavitation

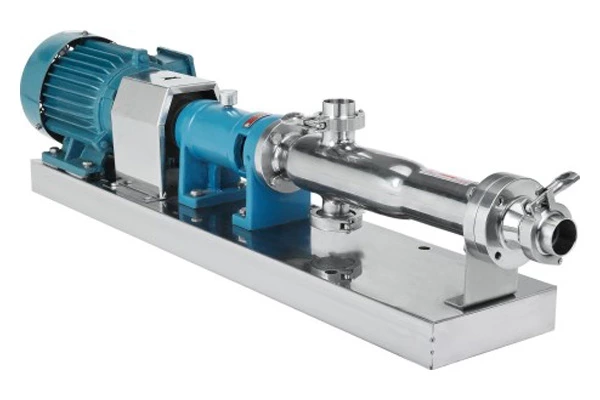

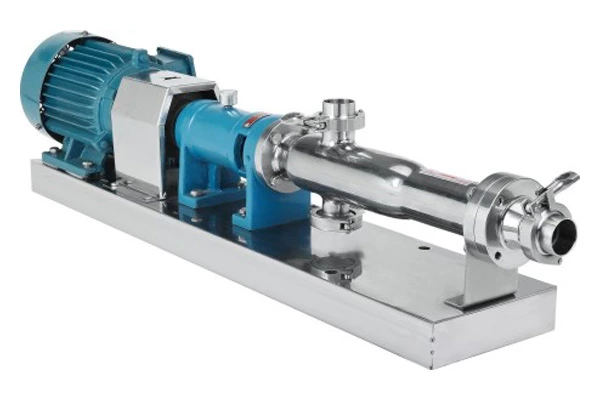

1. Measures to improve the effective cavitation margin of the Solid-Liquid Mixing Pump liquid inlet device

(1) Change the water pump suction device to a backflow device;

(2) Reduce the installation height of the water pump suction device;

(3) Increase the pressure of the liquid surface in the liquid storage tank in front of the pump to improve the effective cavitation margin of the water pump.

(4) Reduce the flow loss in the pipeline in front of the pump, such as shortening the pipeline as much as possible within the required range, reducing the flow rate in the pipeline, reducing the number of bends and valves, and increasing the valve opening as much as possible.

2. Measures to improve the anti-cavitation performance of the water pump itself

(1) Improve the structural design of the pump from the suction port to the impeller. Increase the flow area, increase the radius of curvature of the impeller cover inlet section, reduce the rapid acceleration and pressure drop of the liquid flow, appropriately reduce the thickness of the blade inlet, and round the blade inlet to make it close to the streamline shape, which can also reduce the acceleration and pressure drop of the flow around the blade head, improve the surface finish of the impeller and blade inlet to reduce resistance loss, extend the blade inlet edge to the impeller inlet, so that the liquid flow receives work in advance and increases the pressure.

(2) Use a double-suction impeller to allow the liquid flow to enter the impeller from both sides of the impeller at the same time, then the inlet section is doubled and the inlet flow rate can be reduced by half.

(3) Use a pre-inducing impeller to allow the liquid flow to do work in advance in the pre-inducing impeller to increase the liquid flow pressure.

(4) Use anti-cavitation materials. Practice shows that the higher the strength, hardness and toughness of the material, the better the chemical stability and the stronger the anti-cavitation performance.

(5) The design working condition adopts a slightly larger positive angle of attack to increase the blade inlet angle, reduce the bending at the blade inlet, reduce the blade blockage, increase the inlet area, improve the working conditions under large flow, and reduce flow loss. However, the positive angle of attack should not be too large, otherwise it will affect the efficiency.

3. Reduce the required cavitation margin

Appropriately increasing the impeller inlet diameter and increasing the blade inlet width can reduce the critical cavitation margin of the pump, reduce the impeller inlet speed and relative speed, and reduce the generation of bubbles. The method of using a multi-stage pump impeller, an induction wheel and an induction wheel to generate a pressure wheel to work together after coaxial assembly, and in this process, the pump impeller feed pressure is increased to improve the pump's anti-cavitation performance.

4. Improve the anti-cavitation ability of the flow component data

Selecting materials with strong anti-cavitation pump components to effectively reduce the damage of the flow components of the pump and extend the service life of the pump. For example, materials such as manganese, bronze and stainless steel can be selected for casting, and the surface is coated with polymer or laser spraying. The anti-cavitation ability of the pump will be enhanced.

5. Improve the anti-cavitation ability of imported equipment

The setting of the pump water inlet equipment and pipeline system is closely related to the cavitation margin. In order to meet the requirements of the dynamic pressure drop of the water pump, it is necessary to plan excellent water inlet equipment to maximize the cavitation margin introduced by the pump manufacturer. Secondly, the water absorption rate of the pump should be reasonably determined, and the various working conditions that the pump manufacturer may encounter during operation should be fully considered. The determined water absorption rate should meet the water absorption rate requirements under any working conditions. In addition, a reasonable air intake pipeline is selected to minimize the length of the horizontal pump water inlet pipe and unnecessary pipe fittings, and appropriately increase the water inlet pipe diameter to reduce the hydraulic loss at the water inlet and improve the cavitation margin at the water pump inlet.