Complete List Of Vacuum Pump Troubleshooting Methods

Vacuum pump installation

(1) The vacuum pump should be installed in a dry, well-ventilated and clean place.

(2) The ambient temperature of the vacuum pump is 5-40℃.

(3) The vacuum pump should be installed horizontally, and sufficient space should be left around it for daily inspection and maintenance. Easy to install and disassemble.

(4) After the power is turned on, the direction of the motor should be in accordance with the direction arrow on the pump.

(5) The pipe connecting the pumped container should be clean and free of impurities and other foreign matter. The aperture should not be smaller than the pump port diameter and the length should be short to ensure that it has sufficient conduction capacity. The pipe connection should be sealed and leak-proof.

(6) No granular solids should enter the pump cavity when the pumped gas is pumped.

(7) The connection between the vacuum pump and the front stage pump should be equipped with an elastic tube to reduce the vibration caused by the front stage pump.

(8) The electrical equipment must have an interlocking protection device. When the front stage pump stops working, the pump must stop at the same time.

(9) Small pumps can be started directly, and large pumps must be equipped with a starter.

Instructions for use of vacuum pump:

After the new pump is in place, check the oil level first. The oil level on the gear side should be such that the oil surface submerges 3-5 teeth. On the motor side, the oil level should be slightly higher than the center of the oil window. The oil cup on the shaft extension should not be short of oil. The lubricating oil for each part should use No. 1 vacuum pump oil.

1. Vacuum pump starting procedure:

(1) Start the foreline pump.

(2) Open the valve of the foreline pump pre-pumping official route and the valve on the pump inlet.

(3) After the pressure in the system reaches the allowable pressure of the vacuum pump, close the pre-pumping valve and start the vacuum pump. If there is no pre-pumping pipeline and valve, start the vacuum pump after reaching the starting pressure. This process can also be automatically controlled by a pressure sensor to realize the automation of the entire process.

(4) According to the actual situation of the vacuum system, if it is not a large vacuum system, the vacuum pump can be started after starting the foreline pump. If it is a larger vacuum system, although the vacuum pump with overflow valve has overload protection, this protection is only for the motor. The pump itself may still be stuck due to overheating due to long-term operation under high pressure. The pump should be started after the front pump reaches a certain pressure.

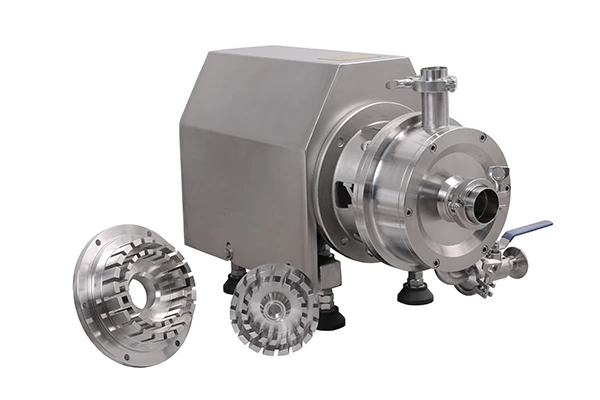

2. CIP Return Pump parking procedure:

(1) Close the vacuum pump inlet valve.

(2) Stop the vacuum pump step by step from top to bottom, and finally stop the front pump. It is strictly forbidden to make mistakes in the parking procedure.

(3) After the front pump stops, immediately vent the air inlet of the front pump.

3. Points to note during the operation of the vacuum pump:

(1) The vacuum pump must be used in accordance with the technical specifications during operation. Under normal circumstances, the inlet pressure of the vacuum pump is below 1330Pa, and the maximum pressure difference of the pump shall not be higher than its maximum allowable pressure difference value.

(2) Pay attention to the motor load and the temperature rise of various parts of the pump. Under normal operation, the maximum temperature rise of the pump shall not exceed 40℃, and the maximum temperature shall not exceed 80℃. If a water ring pump is used as the front pump, the temperature rise of the pump may increase due to the large ratio of the pumping speeds of the two pumps, but the maximum temperature of the pump shall not exceed 100°C.

(3) There should be no irregular abnormal vibration and abnormal noise during operation.

(4) If the motor is overloaded, the temperature rise is too high, the sound is abnormal, the vibration is large, etc., the machine should be stopped immediately to check the cause and eliminate the fault.

Maintenance of vacuum pump:

(1) Check the oil level every day. If the oil level is too high, the temperature will rise. If the oil level is too low, it will cause poor lubrication. Check the quality of the oil every month. If it deteriorates, it must be replaced immediately.

(2) Check the temperature rise of the pump, the motor load and the temperature rise every day.

(3) Check the bearings, oil seals, gears and other parts of the pump regularly. If damaged, they should be replaced.

Faults and troubleshooting methods of vacuum pumps:

1 Fault phenomenon: The pump does not pump enough air

Causes;

(1) The speed of the vacuum pump is not enough;

(2) The seal is not tight, and there is leakage at the connection of the air inlet pipe or the shaft seal;

(3) The gap between the pump rotor and the rotor, the outer circle of the rotor and the pump shell, and the end face of the rotor and the end cover is too large, and the gas return volume increases;

(4) The ambient temperature or the temperature of the cooling water is too high.

Troubleshooting methods:

(1) If the pump speed is not enough and the air suction volume is proportional to the pump speed, the pump suction volume will decrease. There are two situations; one is that the pump speed is not equipped well, that is, the diameter of the pulley is not suitable. The pulley can be replaced to change the diameter of the pulley; the other may be that the belt is improperly installed and not tightened, and the belt slips and reduces the speed. In this case, the motor position can be adjusted to make the belt tighten to a certain degree.

(2) Find out where the air leaks. If it is leaking at the connecting flange, it may be due to loose connecting screws, crushed gaskets or uneven flange surface processing; if it is leaking at the shaft seal, it may be that the sealing cup is not installed properly or is broken. In this case, replace the cup and install it properly; if it is a packing seal, the inserted packing can be taken out and replaced with a new one, but the interface of the packing must be inclined and overlap each other tightly. The interface of the first circle must be staggered with the interface of the second circle and cannot be in the same position.

(3) If the gap between the rotor and the rotor profile is uneven, the gap is large in the middle of the circle and small in the other place. This is because the meshing condition of the synchronous gears was not adjusted properly during assembly. In this case, the gear of one of the synchronous gears is fixed as a hub, and the hub of the other gear is made adjustable, because the appearance of the two rotors is a conjugate surface and they must mesh with each other normally. At the same time, the transmission gear (synchronous gear) at the outer end must also be in a normal meshing state so that the spokes can transmit normally. Otherwise, even if it can rotate, the gap between the two rotors may be large or small in the crown.

In this state, loosen the screws connecting the adjustable gear to the hub and pull out the positioning pins to adjust so that the meshing of the rotor and the meshing of the gear can reach the normal meshing state at the same time. At this time, the gaps at all places are uniform. Re-tighten the screws, re-hash the pin holes and install the pins for positioning. If the gap between the outer diameter of the rotor and the pump casing is too large at one place, loosen the connecting screws between the end cover and the pump casing, pull out the positioning pins, adjust, and wait until the gaps at all places are uniform, then tighten the screws, re-hash the positioning pin holes between the end cover and the pump casing and install the cone pins.

(4) When the ambient temperature rises, the suction volume will decrease. In this case, try to reduce the injection water temperature.

2 Fault phenomenon: The vacuum degree is not high enough

Causes:

(1) The air intake system is not sealed tightly and there is air leakage;

(2) The pump itself is not sealed tightly and there is air leakage at the shaft seal;

(3) The gap between the rotor and the rotor or between the rotor and the housing is too large, and the air temperature is too high:

(4) The pressure difference between the inlet and outlet gas medium of the pump is too large.

Troubleshooting method:

The solution to the first three faults is the same as the above method. Among them, if the air temperature is too high, the vacuum degree will be reduced. If it is a wet pump, cold water can be injected at the air inlet. If it is a dry pump, a cooler can be added to the air outlet to reduce the air temperature. There are many reasons for the excessive pressure difference in (4). If it is a dry pump, check whether the safety valve (relief valve) is malfunctioning. If it is malfunctioning, the outlet pressure may be too high. If it is a wet pump, it may be caused by excessive outlet water seal pressure or too small outlet pipe diameter and too many elbows, which increases the outlet resistance. Troubleshooting should be carried out according to the actual situation.

3 Fault phenomenon: It is difficult to restart the pump after stopping

Cause:

Sometimes, when the pump is running continuously, no abnormal phenomenon is found. Once it stops running for a short time, it is difficult to restart or even cannot start. If it is a wet pump, the following reasons may be the cause:

(1) The scale on the inner wall of the pump casing and the outer surface of the rotor is too thick, blocking the gap;

(2) When installing or replacing the air intake pipe, the pipe is not cleaned well, causing welding slag or other hard debris to enter the pump;

(3) The rotor is in a cross-position, and the end of the rotor rubs against the end cover, increasing the resistance;

(4) The rotor shaft is bent, and the rotor or synchronous gear is stuck.

Troubleshooting method:

(1) Some of the cooling water entering the pump is untreated hard water, which is too heavy in calcium and produces deposits in the pump. Especially when the untreated hard water is working at a temperature of 50-60℃ in the pump, it is easier to deposit and become scale to block the gap of the pump. There are two solutions: one is mechanical method, which is to use a shovel or scraper to remove the scale, and the other is chemical method, which can use hydrochloric acid with a concentration of 5% to 10%. Among them, after the chemical method is used to remove the scale, it must be washed with steam and water to prevent the equipment from being corroded. In order to avoid serious scaling, the cooling water should be treated with clean cold water with a temperature below 20°C;

(2) Before installing the pipe, be sure to clean the inside of the pipe. If conditions permit, first wipe the inner wall of the pipe clean, and then blow it with compressed air;

(3) Take out the rotor and reassemble it, and find out the reason, and deal with it appropriately according to the specific situation;

(4) Take the rotor out of the pump housing and place it on two parallel and equal-height blades or a similar bracket. Use a micrometer to check whether the rotor shaft is bent and the size and direction of the bend. If the bend is small, use a press to straighten it. If the bend is large, it needs to be replaced.

4 Fault phenomenon: The noise of the pump increases when it is running

Causes:

(1) The gap between the rotors or between the rotors and the casing is uneven or inappropriate, resulting in friction. In this case, the noise can increase dramatically;

(2) The synchronous gears are not meshing well, or the gap between the teeth is too large, or there is a lack of lubricating oil in the gearbox, and the teeth are in a dry friction state. At this time, the noise in the gearbox will also increase dramatically:

(3) The speed of the pump is too high, and the working medium (air and water) has a violent collision in the pump cavity and the pressure regulating box, and even the pump vibrates, which of course increases the noise.

Troubleshooting method:

Carefully analyze and listen to find out where the noise comes from, and then find out the cause of the noise. There are also ways to reduce the noise.

(1) If the noise is generated by friction between the rotors or between the rotor and the pump housing, it can be detected by hearing. Carefully adjust the rotor clearance according to the method described above so that all clearances meet the requirements:

(2) Loosen the hub connection screw of one of the synchronous gears, that is, the gear on which the hub is mounted, and pull out the positioning pin, and rotate the gear ring to make it mesh normally. Add enough lubricating oil to the gearbox as required to overcome dry friction, and the noise will naturally decrease;

(3) If the speed is indeed too high, the pulley can be replaced to reduce the speed, or a muffler can be added to the outlet side of the voltage regulator box at the same time.