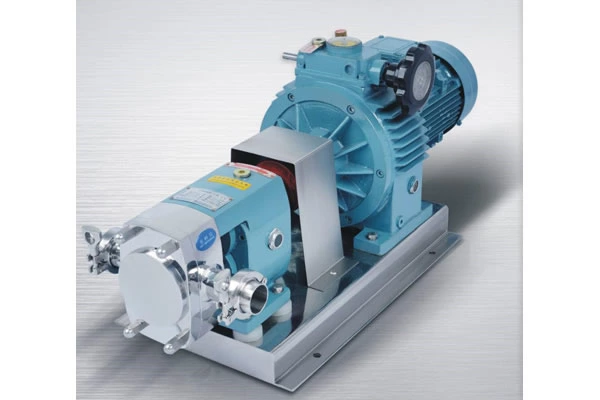

Common Knowledge On The Use And Maintenance Of Sanitary Rotary Lobe Pumps

Sanitary Rotary Lobe Pump is the main type of actuator, which receives the control signal output by the modulation unit. The sanitary rotary cam pump uses power operation to change the fluid flow. There are four types of materials for sanitary rotary cam pumps: plastic, aluminum alloy, cast iron, and stainless steel. The sanitary rotary cam pump uses nitrile rubber, chloroprene rubber, fluororubber, polyvinylidene fluoride, and polytetrahexaethylene according to different liquid media. To meet the needs. It is placed in various special occasions to pump various media that conventional pumps cannot pump.

The sanitary rotary cam pump is a corrosion-resistant pump, mainly used for the transportation of corrosive liquids. Here is a brief introduction to the use and maintenance of the sanitary rotary cam pump.

1. Check whether there is any looseness at the joints of the pump and pipeline. Turn the pump by hand to see if the pump is flexible, and then try to see the direction of the motor.

2. Add bearing lubricating oil to the suspension and observe that the oil level should be between the two lines of the oil mark.

3. Unscrew the water inlet screw of the pump body and fill it with water.

4. Close the gate valve of the outlet pipe, the outlet pressure gauge and the inlet vacuum gauge.

5. Start the motor. When the pump is running normally, check the outlet pressure gauge and the inlet vacuum gauge. After the appropriate pressure is displayed, gradually open the gate valve and check the motor load.

6. Try to control the flow and head of the pump within the range indicated on the pump nameplate to ensure that the sanitary rotary cam pump operates near the high efficiency point for a long time to achieve the maximum energy saving effect.