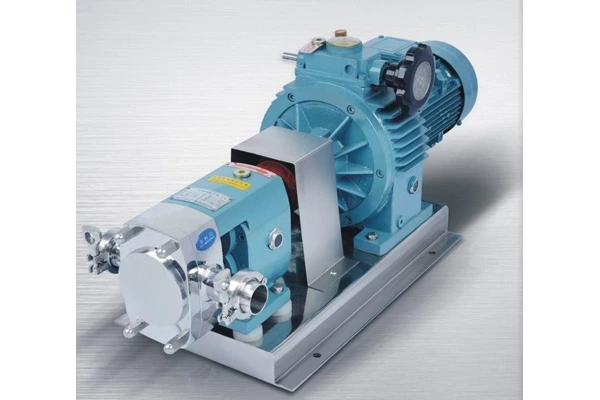

Common Faults And Solutions For Sanitary Rotary Cam Pumps In Water Treatment Equipment Systems

1. What is the possible reason for the insufficient flow of Sanitary Rotary Lobe Pump? How to solve it?

(1) There is air in the water pump---Solution: bleed air.

(2) The sealing ring of the water pump is damaged---Solution: replace the sealing ring.

(3) There is air leakage at the packing---Solution: apply some butter on the packing and tighten the packing pressure plate.

(4) The speed of the water pump is too low, is the voltage too low?---Solution: try to increase the voltage.

(5) The impeller, water inlet, and pipe are blocked---Solution: remove debris.

(6) The impeller is worn too much---Solution: replace the impeller and check the bearing wear.

(7) The motor is not rotating in the right direction---Solution: adjust the phase.

(8) The center line of the impeller is not immersed in the liquid---Solution: adjust the immersion height.

2. What is the possible reason for the heating of the water pump bearing? How to solve it?

(1) The main shaft and the motor shaft are not concentric---Solution: adjust the concentricity.

(2) The bearing cover lacks oil or the oil is deteriorated---Solution: Add oil or change oil.

3. What is the possible reason for insufficient head of the water pump? How to solve it?

(1) The impeller is damaged---Solution: Replace another part.

(2) The speed is insufficient---Solution: Check whether the voltage and motor are normal.

(3) There is gas in the infusion---Solution: Reduce the liquid temperature to remove the gas.

4. What is the possible reason for vibration or noise of the water pump? How to solve it?

(1) The main shaft and the motor shaft are not concentric---Solution: Adjust the concentricity.

(2) The rotor is unbalanced---Solution: Replace another part.

(3) The nuts are loose---Solution: Tighten the nuts at all parts.

(4) There is gas in the infusion or it is running without liquid---Solution: Reduce the liquid temperature, remove the gas, and put the impeller into the liquid.

(5) The water bearing and the journal are worn too much---Solution: Replace the water bearing and restore the shaft strength.

5. What are the possible reasons for the low or no liquid output of the water pump? How to solve it?

(1) The motor is not rotating in the right direction---Solution: adjust the phase.

(2) The center line of the impeller is not immersed in the liquid---Solution: adjust the immersion height.

6. What are the possible reasons for the power overload of the water pump? How to solve it?

(1) The specific gravity of the medium is too large---Solution: replace a larger power motor.

(2) The flow rate exceeds the use range---Solution: work within the use range.

(3) Mechanical friction is generated---Solution: check and adjust or replace worn parts.