Cip Reflux Pump Selection Principles

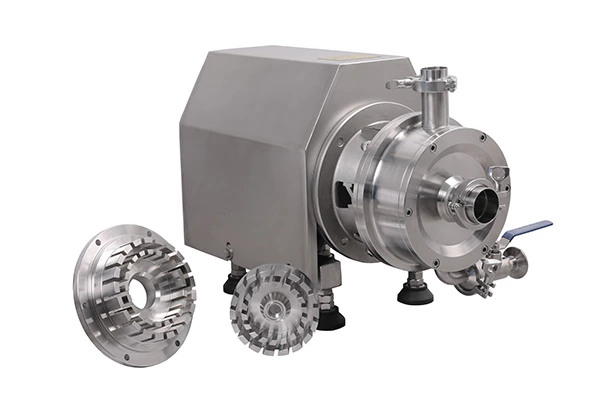

CIP Return Pump adopts the pump body structure of axial liquid return. The pump body consists of suction chamber, liquid storage chamber, vortex chamber, liquid return hole, gas-liquid separation chamber, etc. The pump bearing adopts single-row radial ball bearing. There is a cooling chamber at the bottom of the pump bearing body, and there are sealing rings in the high and low pressure areas inside the pump. The shaft end adopts mechanical seal.

The CIP return pump is equipped with a bottom valve at the bottom of the suction pipeline. Before starting, more water is needed to fill the entire suction pipeline. The bottom valve often fails due to the inclusion of debris or its own poor sealing. It sometimes takes a lot of labor to eliminate these failures, especially in winter. The suction inlet of the CIP return pump is generally higher than the impeller suction inlet. It can be started as long as water is injected into the pump body without the above defects. It is very convenient to use CIP return pumps in occasions such as mobile irrigation and drainage, mobile work, frequent starting and water injection problems. Self-priming pumps are used in many places such as agriculture, construction, oil tanker unloading, oil depots, firefighting and shipbuilding.

CIP reflux pump selection principles:

1. High mechanical reliability, low noise, and low vibration

2. Make the type and performance of the selected pump meet the requirements of process parameters such as device flow, head, pressure, temperature, cavitation flow, and suction distance.

3. Economically, the total cost of equipment fees, operating fees, maintenance fees, and management fees should be comprehensively considered to be the lowest.

4. CIP reflux pumps have the characteristics of high speed, small size, light weight, high efficiency, large flow, simple structure, no pulsation during infusion, stable performance, easy operation and convenient maintenance.

CIP reflux pumps are used to transport petroleum products such as gasoline, kerosene, diesel, and aviation kerosene. The medium temperature is between -20℃ and +80℃. It is an excellent ship loading and unloading oil pump that can also be used as a tank water pump. It is also suitable for oil transportation in oil storage devices such as land oil depots and tank trucks. It can also be used to transport seawater, fresh water, etc. It has the characteristics of simple structure, convenient operation and maintenance, stable operation, large displacement, high efficiency, easy adjustment, strong self-priming ability, and a wide range of applications.

CIP return pumps are widely used in sewage discharge of municipal engineering, factories, businesses, hospitals, hotels, residential areas, etc. due to their advantages of simple installation, small footprint, convenient maintenance, and no noise. At present, CIP return pumps in China are mainly produced and manufactured by domestic manufacturers, and a small number of products are imported from abroad. The market prospect is very broad.