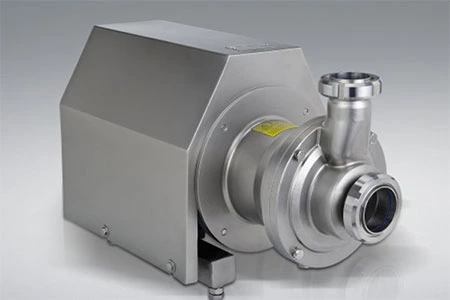

Centrifugal pump selection, use method and maintenance①

1. Selection and installation of centrifugal pump

The sanitary pump should be selected according to the liquid to be transported, and the required performance should be checked, and the suction and discharge conditions should be analyzed, whether it is intermittent or continuous operation, etc. Centrifugal pumps should usually be operated at or close to the pressure and flow conditions specified by the manufacturer. The following re-checks should be carried out during the installation of the negative pressure pump : ① The size, position and elevation of the foundation should meet the design requirements, the anchor bolts must be properly and correctly fixed in the concrete foundation, and the machine should not be missing, damaged or rusted; ②According to the characteristics of the medium conveyed by the pump, the materials of main parts, shaft seals and gaskets should be checked if necessary; ③The leveling and alignment of the pump should comply with the regulations of the equipment technical documents, if there are no regulations, it should comply with the current country The requirements of the standard "General Specification for Construction and Acceptance of Mechanical Equipment Installation Engineering"; ④ All the pipes connected to the pump body, the installation of pipe fittings and the cleaning requirements of the lubricating oil pipes should meet the requirements of the relevant national standards.