Causes And Technical Solutions For Noise Generated By Emulsification Pumps

Emulsification Pump seals are usually divided into mechanical seals, packing seals and emulsification pump PTFE dynamic tongue seals. When selecting emulsification pump seals, you should choose according to the specific application needs of the customer. You cannot just consider the customer's needs for the temperature of the emulsification pump. It is necessary to consider the length, height, diameter and resistance of the actual pipeline from the customer's point of view to consider which seal should be selected.

Temperature resistance of emulsification pump bearings. The speed of the emulsification pump is relatively high, so the emulsification pump bearings must use high-speed bearings. In order to avoid the influence of heat conduction when the emulsification pump is working at high temperature, the emulsification pump bearings usually use high-temperature resistant bearings. The specific brands of emulsification pump bearings commonly used in China are Korean KBC, and usually small flow pumps are equipped with a bearing at both ends of the shaft on each emulsification pump. In particular, large flow and emulsification pumps must be equipped with two bearings at both ends of the shaft to ensure the stability of the emulsification pump main shaft under large flow and large centrifugal force.

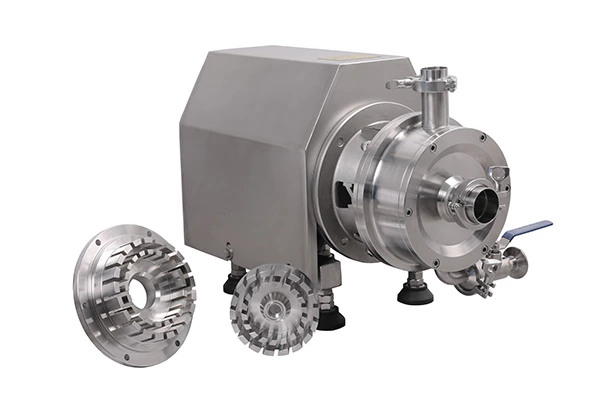

The emulsification pump impeller needs a long-term reaction period before installation. After the reaction period, the impeller can be fine-machined. After the processing, the emulsification pump impeller must be tested for static balance and dynamic balance before the emulsification pump can be installed. Static balance or dynamic balance will cause the emulsification pump to have loud noise, large vibration, and simple bearings and seals after operation. It is very good to improve the rationality of processing and ensure the concentricity of each accessory. Emulsification pumps have been digesting and absorbing foreign advanced technologies and independent innovation for more than 20 years, especially through a number of national important technical equipment - large-scale synthetic ammonia.

The research and development of key equipment for large-scale urea and large-scale ethylene cracking and post-processing has made a leap forward in China's emulsification pump equipment manufacturing industry. For the emulsification pump industry based on ethylene cracking, although there is currently no ability to supply complete sets of equipment in China, the key development of emulsification pumps has made significant progress in recent years: ethylene cracking furnaces and their quenching boilers, various low-temperature pumps, plate-fin heat exchangers with a pressure of 7.8MPa, large ethylene spherical tanks, polypropylene reactors, and large twin-screw granulation units have been successfully developed.

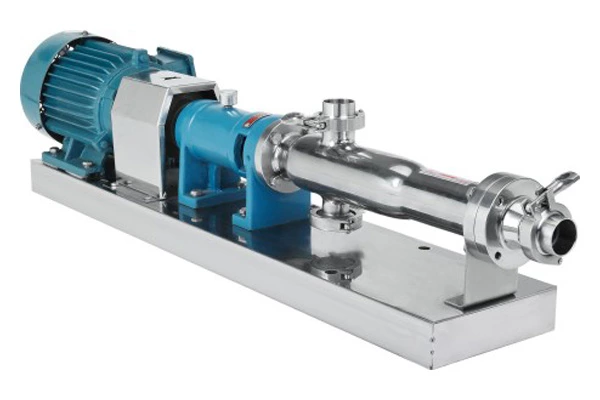

Emulsification pumps are suitable for conveying high-temperature liquids without solid particles. Its corrosion resistance and operating temperature depend on the materials of the main parts in contact with the medium. The emulsification pump adopts a self-heating and heat dissipation structure, which changes the traditional water cooling structure, making the structure simple, small in size, saving operating costs, good in performance, and reliable in use. It is the second-generation product developed on the basis of my country's digestion and absorption of foreign emulsification pumps. The basic structural form is a single-stage single-suction cantilever foot support structure. The inlet of the emulsification pump is axial suction, and the outlet is vertically upward with the center, and it is installed on the base together with the motor.