Causes And Solutions For The Vibration And Noise Of Cip Return Pump

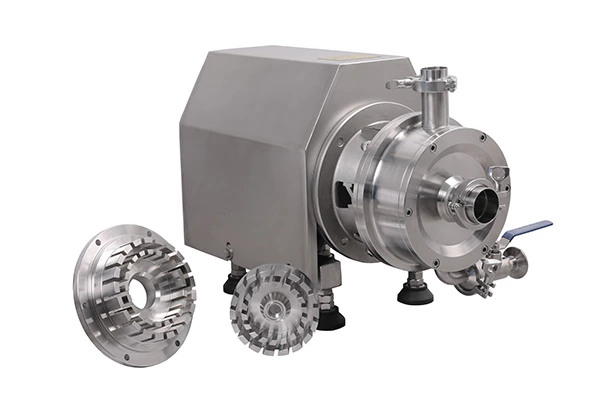

CIP Return Pump The principle is simply that when the impeller rotates at high speed, it drives the liquid between the blades to rotate. Due to the centrifugal force, the liquid is thrown from the center of the impeller to the outer edge of the impeller, and the kinetic energy increases accordingly. When the liquid enters the pump casing, the flow channel in the volute-shaped pump casing gradually expands, the liquid flow rate gradually decreases, and part of the kinetic energy is converted into static pressure energy, so the liquid flows out along the discharge port at a higher pressure. Since the CIP return pump mainly relies on the centrifugal force to transport liquid, it is called a CIP return pump. If not handled properly, the centrifugal force generated by the impeller will cause the pump to vibrate and make abnormal noise.

When the CIP return pump is used, if the pump vibration and noise are abnormal, it should be stopped immediately for inspection.

1. Is the pump foundation reliable?

When vibration occurs, first check whether the anchor bolts of the CIP return pump are tightened. If not tightened, the CIP return pump will vibrate. It is also necessary to consider whether the foundation strength is sufficient. Sometimes due to design reasons, a soft foundation can also cause vibration.

2. Alignment of couplings

Many CIP return pumps are driven by couplings, and there are many types of couplings. The alignment of conventional three-claw couplings directly affects the normal operation and service life of couplings, shafts, bearings, mechanical seals, etc.

3. Centering

Misalignment of the center is also a common cause of vibration. The center must be adjusted within the specified range in strict accordance with the standard.

4. Bearing inspection.

Whether there is a problem with the bearing installation or whether it is damaged.

5. Adjust the rotor center position.

The pump rotor should be concentric with the stator, otherwise friction and vibration will occur when the pump is running.

6. Shaft bending and rotor measurement

If the cause of the vibration cannot be found externally, the pump can only be disassembled. Measure and correct the shaft bending first, and then install the rotor after there is no problem, and measure the overall wobble and scoop deviation. If it exceeds the standard, it must be corrected.

7. Dynamic and static balance detection.

After the CIP return pump is disassembled, in order to avoid vibration when the pump is turned on, the impeller should also be subjected to a static balance test.

The impact of external conditions on the water pump.

When all possible problems with the water pump itself are eliminated, if the vibration problem still cannot be solved, the impact of external conditions on the water pump should also be considered. For example, resonance caused by the natural frequency of the water pump foundation being similar to the vibration frequency, water pump vibration caused by prime mover failure, and strong connection between the pipe and the water pump can also cause abnormal vibration of the water pump. Generally, taking appropriate measures can solve the problem.