Assembly And Disassembly Of Sanitary Centrifugal Pumps

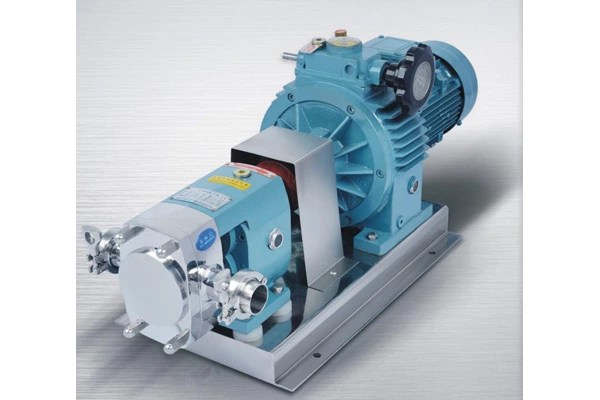

Sanitary Centrifugal Pump is a corrosion-resistant pipeline pump based on the GD pipeline centrifugal pump. All the flow-through parts are made of SUS304/316 stainless steel. The pump mechanical seal adopts corrosion-resistant mechanical seal, which is corrosion-resistant, long-life, and leak-free during long-term operation. The inlet and outlet are of the same size and located on the same straight line. The pump can be installed on the pipeline like a valve. The upper cover structure allows the pump to maintain the mechanical seal or impeller and motor without removing the pipeline part, which facilitates installation and daily maintenance. The sanitary centrifugal pump adopts standard SUS304/316 stainless steel and is molded by casting, which improves the corrosion resistance of the pump.

Assembly and disassembly of sanitary centrifugal pump:

1. Clean all the parts to be installed from the stainless steel pipeline pump.

2. Install the mechanical seal on the motor main shaft, and add a small amount of clean turbine oil or No. 20 engine oil on the surface where the dynamic and static rings of the mechanical seal match.

3. Install the impeller and tighten it with the impeller nut.

4. Install the "F4" gasket and tighten the pump body and the bracket with screws.

5. The disassembly order is the opposite.

Installation and use of sanitary centrifugal pumps:

1. Use gaskets and bolts to connect the flanges at both ends of the pump body to the pipeline flanges to complete the installation. For the convenience of use and maintenance, a regulating valve should be installed on the inlet and outlet pipelines of the pump.

2. Open the inlet regulating valve to allow water to enter the pump to keep the sealing chamber full of liquid (otherwise it will damage the seal), and close the outlet valve.

3. Turn on the power and jog to determine the correct direction

4. After the direction is determined, start and run the pump.

5. Adjust the outlet valve opening to make the pump run near the design point, according to the rated flow and head of the pump. (For this reason, it is best to install a pressure gauge near the outlet flange)

In summary, whether it is airplanes, rockets, tanks, submarines, or drilling, mining, trains, ships, or daily life, vertical pipeline centrifugal pumps are needed everywhere in the world, and sanitary centrifugal pumps are running everywhere throughout the year. Because of this, sanitary centrifugal pumps are classified as general machinery. Sanitary centrifugal pumps are an indispensable and most important type of product in the machinery industry.